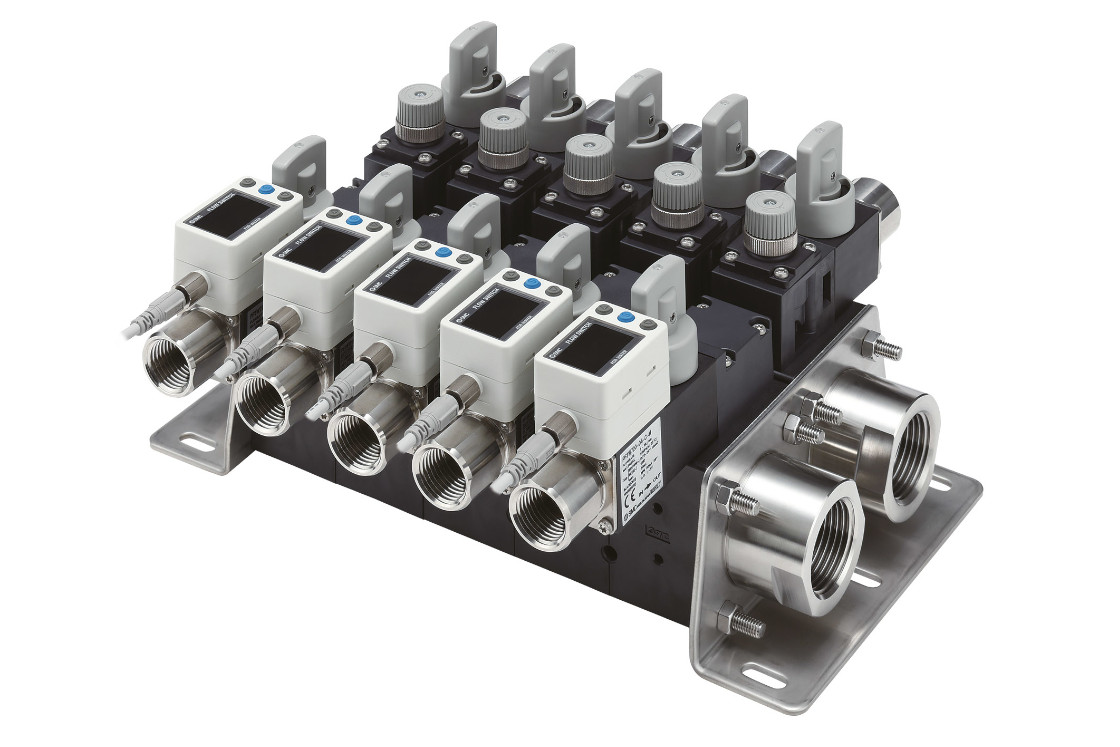

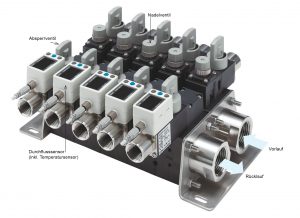

With the flow sensors from SMC you can easily and reliably monitor up to 10 stations simultaneously. And in the smallest space!

We at SMC help you to make your processes as efficient and stable as possible. The cooling water distribution is always an important issue – from assembly to maintenance.

Modular cooling water distribution made easy

The modular flow sensors of the PF3W series help you save. Namely space, time and money. The sensors are space-saving and compact and monitor up to 10 stations simultaneously. And with flow ranges from 0.5 to 4 liters, 2 to 16 liters or even 5 to 40 liters per minute and line.

The PF3W series scores with many advantages: All media-contacting materials are copper-free and therefore suitable for DI water, have an integrated flow and return unit and are already fully assembled. This makes installation particularly easy and inexpensive and reduces the possibility of leakage to a minimum.

The distribution of the cooling medium is set via a needle valve and you can shut off the individual strands independently of one another for maintenance work, which saves you a lot of time in the operational sequence.

Reliable flow sensors for your processes

Reliable flow sensors for your processes

Another important topic is temperature monitoring. Integrated two-color displays ensure that you can see all relevant information for each individual line at a glance. In this way you can recognize process changes in good time and can always check whether the cooling function is ensured.

The Karman vortex measuring principle in our flow sensors does not require any moving parts, which significantly increases the service life.

Further advantages: simple implementation, a digital switching output and an analog output. Of course, the SMC flow sensors are I / O compatible and can be combined with SMC temperature control units.

Where are flow sensors used?

Many processes depend on safe cooling. The flow sensors from SMC are therefore used in various industries. For example in laser temperature control, where precise cooling devices ensure constant temperatures. The coolant distribution is an important part so that the optical components of the laser are not changed by temperature differences and the laser can continue to work precisely.

The flow sensors of the PF3W series are a guarantee for consistent quality even in water-cooled welding. This enables process changes to be recognized and remedied in good time, which increases the lifespan of the components enormously and at the same time greatly reduces maintenance.

Of course, many other industries and processes also benefit from modular cooling water distribution and monitoring. We are happy to help!

Would you like to know more about the flow sensors of the PF3W series? You can download our catalog here.

DE

DE CZ

CZ HU

HU PL

PL SI

SI