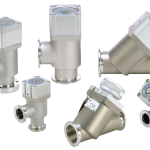

Our high vacuum valves score with long service life and tightness, are extremely corrosion-resistant and are driven pneumatically, electromagnetically or manually. We have models with flange sizes from 16-160, high-vacuum media valves for pressures of 10 bar on the inlet side and 1 × 10-8 mbar on the outlet side and much more.

The excellent thermal conductivity of the high-vacuum angle valves of the XL series guarantee a uniform temperature across the entire valve body and reduce the condensation of gases in the valve to a minimum. These high vacuum valves contain no heavy metals such as nickel or chrome and score with low outgassing.

The excellent thermal conductivity of the high-vacuum angle valves of the XL series guarantee a uniform temperature across the entire valve body and reduce the condensation of gases in the valve to a minimum. These high vacuum valves contain no heavy metals such as nickel or chrome and score with low outgassing.

Catalog valves with large flanges

Our bestselling valves of the XLA and XLD series are also available with quick release as XLAQ and XLDQ. This makes it possible to open the valve quickly and easily without tools. This means that the valve can be cleaned or serviced much more quickly. The flanges do not have to be loosened! The XL * Q series is made of a special aluminum alloy. This makes it possible to heat the valve body extremely evenly. This prevents condensation in the valve, which has a negative impact on the vacuum level. The valves can also be ordered with a heating element. In addition to the extra easy maintenance, the valve scores with a long service life and high resistance to corrosion. Let this valve convince you!

Our bestselling valves of the XLA and XLD series are also available with quick release as XLAQ and XLDQ. This makes it possible to open the valve quickly and easily without tools. This means that the valve can be cleaned or serviced much more quickly. The flanges do not have to be loosened! The XL * Q series is made of a special aluminum alloy. This makes it possible to heat the valve body extremely evenly. This prevents condensation in the valve, which has a negative impact on the vacuum level. The valves can also be ordered with a heating element. In addition to the extra easy maintenance, the valve scores with a long service life and high resistance to corrosion. Let this valve convince you!

Particles can be a big problem in high vacuum chambers – you should stir them up as little as possible. You can do this by slowly and gently reducing the pressure in the chamber. That is why SMC developed the XLD series. The valve can be opened in two stages. Depending on the level selected, the pump is pumped out faster or slower.

The XLD series is part of the XL * family and fulfills all quality criteria.

The housing material of the series XM (high vacuum angle valve) and XY (high vacuum in-line or tube valve) is made of stainless steel. XM and XL have the same dimensions and can therefore be exchanged as required. The valves are cast individually and precisely, which prevents defects such as gas pockets or porous spots.

The housing material of the series XM (high vacuum angle valve) and XY (high vacuum in-line or tube valve) is made of stainless steel. XM and XL have the same dimensions and can therefore be exchanged as required. The valves are cast individually and precisely, which prevents defects such as gas pockets or porous spots.

Depending on the product variation, this high vacuum media valve can withstand an operating pressure of maximum 10 bar (IN side) and a minimum operating pressure of 10-8 mbar (OUT side). It is corrosion-resistant, light and extremely energy-efficient in operation.

Application:

If the high vacuum chamber is ventilated too quickly (clean air / N2), turbulence occurs and in this way undesirable particles get into the high vacuum chamber.

The adjustable high vacuum valve XVD2 enables slow, controlled and therefore practically turbulence-free ventilation of the high vacuum chamber. This makes it possible to keep the number of particles in the chamber as low as possible.

The rectangular gate valve of the XGT series offers high quality for partitioning loadlock, transfer and process chambers.

Additional advantages:

Application: For the production of semiconductors and solar cells

The rodless cylinder for high vacuum chambers was specially developed for minimal particle formation, low leakage and outgassing.

The ZSE80 is available with PNP or NPN outputs and optionally also with an analog voltage or current output as a sensor. The two-color display makes it possible to recognize deviating values at a glance. This product is available in two connection directions (back or bottom) and with different threads (R, NTP, RC, G, URJ (VCR® compatible), TSJ (Swagelok® compatible). With PNP or NPN inputs / outputs and a large one Choice of mounting options Protection class: IP65

The SF series filters are designed for use in clean rooms. All parts of the filter are assembled, checked and packed in the clean room. With the SF series you can choose between two filter elements: membrane or sintered metal. The model with membrane has a filtration of 0.01µm (99.9% efficiency). The filtration of the metal element (SFB2) is 120µm (optional: 1 – 100µm). All filters are tested in production before they are shipped.

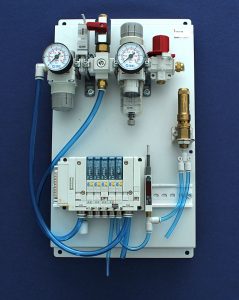

Would you like to make your process safe and effective with a ready-to-install pneumatic control solution?

Would you like to make your process safe and effective with a ready-to-install pneumatic control solution?

We advise and support you in finding the ideal drive solution for your process.

You can find more information about our

Thanks to many years of experience, we can offer complete solutions from (including pneumatic) control to valves and pressure switches. With us you get everything from one source for each of your requirements - no matter how special your wishes are.

Request information

Service is important to us! We have all solutions and designs that are tailored to your wishes and needs. Come on board and enjoy the trust that our long-standing customers have in us.

Contact us

Many of our customers’ modern production methods require special components in the high vacuum range. For example at

High vacuum applications place very high demands on the material and the construction. For this reason, our engineers worldwide work on the optimal solutions for your requirements.

Every high vacuum system requires the highest quality high vacuum valves. Thanks to the excellent thermal conductivity, the temperature of the entire valve body remains constant, deposits of process gases inside the valves are significantly reduced.

We also offer valve series with an optional heating element. They convince with minimal outgassing. Thanks to the low outgassing, a pump can also be used at lower power and the evacuation time (= time to reach the desired vacuum) is reduced. We offer high-vacuum valves made of aluminum that do not contain heavy metals such as nickel and chrome. These heavy metals can cause impurities and thus economy of the process in the manufacture of e.g. B. in microchips (wafers).

Our valves are made of a special aluminum alloy as well as stainless steel in various designs – from the classic angle valve to in-line valves, silt valves, electromagnetic valves to the innovative valve for automatic, even ventilation. Our valves are available in different flange sizes and designs.

What the regular market has to offer is often not enough. That is why our engineers are passionate about developing new and innovative products.

For example, they developed the quick-change high vacuum angle valve of the XL * Q series. what is so special about that? The vacuum valve does not have to be removed for maintenance and service, so cleaning is particularly quick and economical. Another SMC development is the compact two-stage vent valve XVD2, which enables practically turbulence-free aeration.

Do you have higher goals that go far beyond the usual standard? Then come to SMC – our automation experts always have the right solution for you. Benefit from our high-quality, innovative products for efficient production in your company.