Each gas supply system has specific requirements for pressure, flow and material. Benefit from the range of AP Tech products, know-how and technologies to find the optimal solution for your process.

Pressure regulators are essential for any gas installation – as experts in this field we are constantly working to increase the performance, effectiveness and safety of your process.

Whether inert, toxic, corrosive and / or high purity gases, here you will find the right regulator tailored to your needs.

The series AP and AZ (regulators, valves, vacuum generators, …) was developed for operation with a wide variety of high-purity gases in the semiconductor and electronics industries. Each product of this series is assembled and packaged under clean room conditions. Our assortment includes regulators for:

The series AP and AZ (regulators, valves, vacuum generators, …) was developed for operation with a wide variety of high-purity gases in the semiconductor and electronics industries. Each product of this series is assembled and packaged under clean room conditions. Our assortment includes regulators for:

A suitable pressure regulator is essential for any gas supply, because constant and precisely adjustable pressure is as important as choosing the right gas.

A suitable pressure regulator is essential for any gas supply, because constant and precisely adjustable pressure is as important as choosing the right gas.

SMC understands the different requirements for pressure reducers in analytical, technical, food and medical applications and offers you innovative and cost-effective solutions for your process.

Whether high purity, inert, toxic or corrosive gases, we have the right controller for your needs.

Whether high purity, inert, toxic or corrosive gases, we have the right controller for your needs.

Our assortment includes regulators for:

From hydrogen fluoride to nitrogen, our diaphragm valves are always reliable! Long life, high chemical resistance and reliability make the valves ideal for critical and demanding processes.

As each process makes individual demands on the components, our range of valves is as diverse as the applications of our customers.

The AP and AZ series are designed for the semiconductor and electronics industries. Each gas component of this series is manufactured and packaged under clean room conditions.

The AP and AZ series are designed for the semiconductor and electronics industries. Each gas component of this series is manufactured and packaged under clean room conditions.

Our offer includes models for:

From hydrogen chloride through ammonia to argon, you can always rely on our diaphragm valves!

The AK valves impress with their high chemical resistance and long service life. This makes them ideal for critical and demanding applications.

Of course, each method makes different demands on the components. That’s why our valve range is as diverse as your processes.

Our offer includes models for:

With One-touch KQG2 fittings you can connect tubes (and threads) easily and quickly. A plug connection makes it possible. Another advantage: only the outer diameter of the tube needs to be known.

The fittings are made of SUS 316 stainless steel. Besides high quality of stainless steel, the fittings are compact and lightweight. The seals are made of FKM. The product is free of grease and oil.

Applicable tubes are: FEP, PFA, Nylon, Soft Nylon, Polyurethane and Polyolefin.

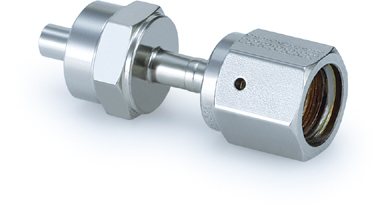

A check valve is a valve that allows gas or liquid to flow in one direction only.

The AP64 defines the new standard for safety and purity. The check valve is completely welded and does not require any springs and poppets. In addition, the design has only one moving part and an O-ring seal.

High quality SS 316L VAR stainless steel double melted and FKM sealing compound (optional neoprene) for a long lasting product with a wide range of uses.

Of course, all parts in contact with the media are electropolished and passivated. Extra low roughness depths (Ra max) of 0.25µm (10µin), 0.18µm (7µin) optionally available. Connection sizes: 1/4 “face seal or ¼“ welded socket.

Suitable for use in clean rooms!

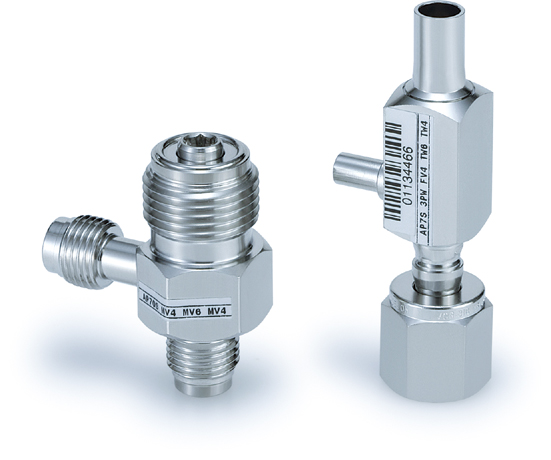

AP Tech offers four different models for vacuum generation and they all have one thing in common – they were developed for maximum efficiency and durability.

AP7 and AP70 are classic vacuum generators. The other two AP71 and AP72 are sophisticated combinations of a vacuum generator, a check valve in the nitrogen line and a valve to switch the nitrogen supply on and off as required.

These modules are a cost-effective alternative to the individual components.

These modules are a cost-effective alternative to the individual components.

Is suitable for use in a clean room!

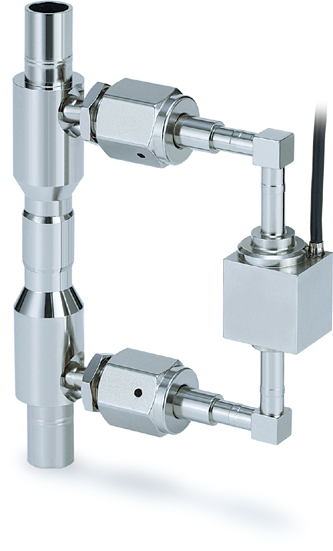

As a specialist for ultrahigh-purity applications in semiconductor, photovoltaic and flat screen manufacturing, we have a special dead-space-free flow switch in our product range. In addition, the design was designed in such a way that the important particle-free operation is possible.

As a specialist for ultrahigh-purity applications in semiconductor, photovoltaic and flat screen manufacturing, we have a special dead-space-free flow switch in our product range. In addition, the design was designed in such a way that the important particle-free operation is possible.

The flow switches, like all of our ultra-pure products, are made from the best SS 316L VAR double-melted stainless steel for optimal durability and an electropolished and passivated surface.

Connection sizes from 1/4 “to 1 1/2“.

Connection sizes from 1/4 “to 1 1/2“.

Suitable for use in the clean room!

Flow switch overview

Useful

Smooth and efficient processes require reliable sensors with maximum performance.

We keep track of your manufacturing processes and make optimal and safe use of resources possible. Trust the excellent quality of our sensors for higher process control, maximum security and best productivity.

Typical product numbers:

PSE560-A2 pressure range 0-1MPa, voltage output, VCR ® compliant connection

PSE560-A2-28 pressure range 0-1MPa, current output, VCR ® compliant connection

PSE560-B2 pressure range 0-1MPa, voltage output, Swagelok ® compliant connection

PSE560-B2-28 pressure range 0-1MPa, current output, Swagelok ® compliant connection

Separate sensor unit.

Separate sensor unit.

The SF series filters are designed for use in clean rooms. All parts of the filter are assembled, checked and packed in the clean room. With the SF series you can choose between two filter elements: membrane or sintered metal. The model with membrane has a filtration of 0.01µm (99.9% efficiency). The filtration of the metal element (SFB2) is 120µm (optional: 1 – 100µm). All filters are tested in production before they are shipped.

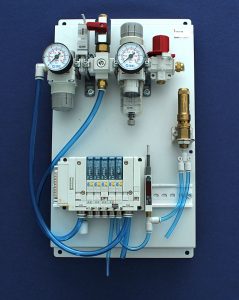

Would you like to make your process safe and effective with a ready-to-install pneumatic control solution?

We advise and support you in finding the ideal drive solution for your process.

You can find more information about our

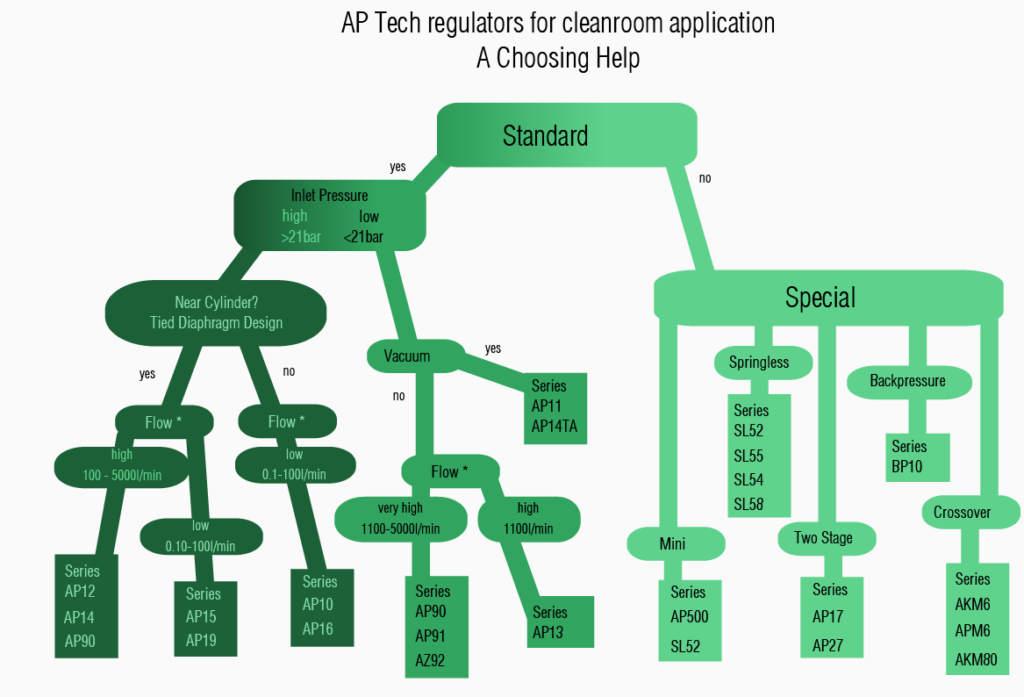

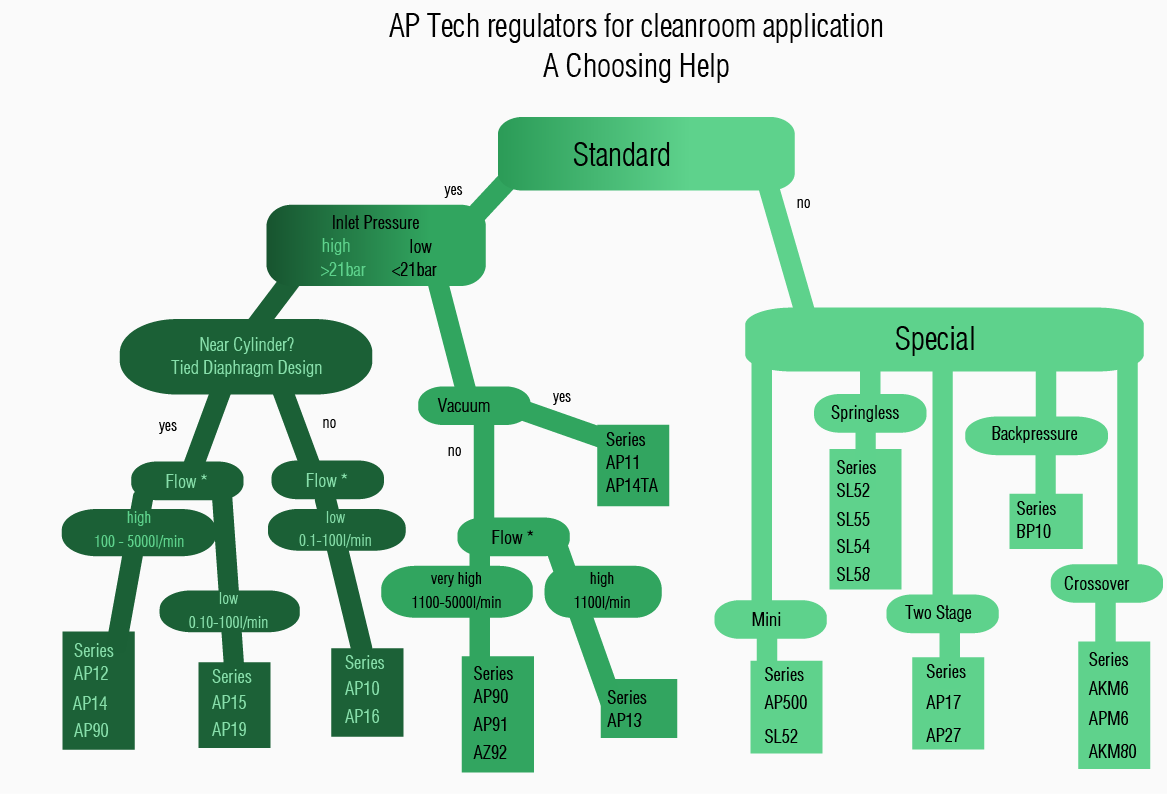

![]() Selection guide for AP Tech controllers and valves

Selection guide for AP Tech controllers and valves

![]() Flow curves of AP Tech controllers

Flow curves of AP Tech controllers

![]() Installation and operating instructions

Installation and operating instructions

![]() Additional technical information about the products

Additional technical information about the products

![]() Additional information about some ordering options

Additional information about some ordering options

Thanks to our many years of experience, we have complete solution of regulators, valves, venturi vacuum generators and sensors for your gas applications. With us you get everything from one source for each of your requirements - no matter how special your wishes are.

Request information

Service is important to us! We have all the solutions and designs that are exactly tailored to your wishes and needs. Come aboard and enjoy the trust our long-standing customers have shown us.

Contact us

High pressure – high flow – near cylinder

AP12 – pdf | AP14 – pdf | AP90 – pdf

High pressure – low flow – near cylinder

AP15 – pdf | AP19 – pdf

High pressure – low flow

AP10 – pdf | AP16 – pdf

Low pressure – very high flow

AP90 – pdf | AP91 – pdf | AP92 – pdf

Low pressure – high flow

AP13 – pdf

Vacuum

AP11 – pdf | AP14TA – pdf

Mini

AP500 – pdf | SL52 – pdf

Springless

SL52 – pdf | SL55 – pdf | SL54 – pdf | SL58 – pdf

Two Stage

AP17 – pdf | AP27 – pdf

Backpressure

BP10 – pdf

Crossover

AKM6 – pdf | APM6 – pdf | AKM80 – pdf

AP Tech (Advanced Pressure Technology) was founded in 1987 by President and CEO Rene Zakhour in the United States. He founded the company with the aim of producing high quality, powerful and reliable products. Right from the start, the focus was on excellent service and technical support. AP Tech is known not only to meet the requirements for ultra-pure technology, but also to meet the individual needs of customers. All products can be easily adapted to a wide variety of needs – and in the shortest possible time. Whether technical or commercial, all inquiries are answered quickly and reliably at AP Tech.

The company has developed into the leading supplier of pressure regulators and valves that are used in many different areas. In addition to manufacturing semiconductor products, AP-Tech’s solutions are also used in other industries and areas, such as the pharmaceutical

The connection sizes range from 1/8 inch to 1 inch and the nominal pressures range from vacuum to more than 600 bar. The products of all series are rigorously tested and meet high quality standards (ISO 9001). The ultra high purity AP and AZ series go through the entire manufacturing, testing and packaging process under clean room conditions.

AP Tech products are particularly suitable for the following industries:

President and CEO Rene Zakhour founded the company with the aim of producing high quality, powerful and reliable products. Right from the start, the focus was on excellent service and technical support.

AP Tech is known not only to meet the requirements for ultra-pure technology, but also to meet the individual needs of customers. All products can be easily adapted to a wide variety of needs – and in the shortest possible time. Whether technical or commercial, all inquiries are answered quickly and reliably at AP Tech.

Our customers are our partners.

As in any good partnership, communication is the be-all and end-all at AP Tech. That is why our customer relationship always begins with a detailed discussion. Tell us what you need and we’ll do our best to make it possible. Are you looking for better solutions, more reliable processes, more efficient production lines? Then you are right with us. Together we will find or find the optimal solution for you.

Of course we want to keep improving. Therefore we are happy if you present us with new challenges. Just get in touch with us. We are here for you!