Temperature controller are used in many heat producing industrial processes (laser, analytics, welding, semiconductors, printing industry, etc.) to monitor and control the temperature.

The temperature control unit of the HRLE Series from SMC has been specially developed for applications with lasers with lower powers. It is used to cool cooling water and can operate two cooling circuits at the same time. The temperature of these can be set independently. As a result, this dual-loop chiller requires 21% less floor space than two individual devices.

The HRLE Series is available in an air-cooled version. It has a total cooling capacity of 8.0 to 9.5 kW – depending on the option selected. In comparison to two individual devices, 17% of electrical energy can be saved. Inverter control can be selected for the pump and the compressor . This can be used to increase the pumping or cooling capacity or also to reduce power consumption.

The temperature stability is ± 0.1 ° C. The circulating medium can be heated even during the winter months without heating. To do this, the hot gas discharged from the compressor is used for heating. The temperature control devices are suitable for all applications in which a medium with a constant temperature is to be fed to a device. The HRLE series primarily cools and temperature-controls lasers in a wide variety of industrial applications such as cutting or welding.

Outdoor installation possible (IPX4)

The temperature control unit of the HRL series from SMC has been specially developed for applications with lasers. It is used to cool circulating water and can handle two cooling circuits at the same time. The temperature of these circuits can be set independently. As a result, this dual-loop chiller requires up to 22% less space than two individual devices.

At the same time it is particularly energy-saving. With a triple inverter, it adjusts the motor speed depending on the load. The chiller uses up to 34% less energy than non-inverter devices. A sealless mechanical immersion pump also ensures that there is no leakage and saves time during maintenance.

The HRL series is available in an air-cooled version. It has a cooling capacity of 10 to 27 kW, with 1 kW being reserved for the second circuit. The temperature stability is ± 0.1°C. The circulating medium can be heated even during the winter months without an electrical heater. To do this, the hot gas discharged from the compressor is used for heating.

The thermo chillers are suitable for all applications in which a medium with a constant temperature is to be supplied to a machine. The HRL series primarily cools and temperature-controls lasers in a wide variety of industrial applications such as cutting or welding.

The Thermo Chiller series HRR adds to the SMC temperature control protfolio. HRR are mounted on 19″ racks. They combine lightweight design with high cooling capacity. The device can do both – heat and cool. Thus the temperature stability is very high.

The Thermo Chiller series HRR adds to the SMC temperature control protfolio. HRR are mounted on 19″ racks. They combine lightweight design with high cooling capacity. The device can do both – heat and cool. Thus the temperature stability is very high.

In addition maintenance is easy. The service lid can be found on the front side. A built in water filter is standard. The flow of fluid can be controlled easily. To achieve that the chiller includes a bypass and a flow sensor as standard. The maintenance can be planned in advance since the chiller will diagnose itself.

Multiple HRR Thermo Chillers can be mounted to a singular rack. As a result they need very little space. They are specialised in the needs of the laser industry. Of course they also have many other applications. For example electron microscopes, digital X-ray machines or the cooling of probes and reagents.

The thermo chillers of the series HRS by SMC Pneumatic for heat extraction of cooling water combine lightweight compactness and highly precise cooling capacity. HRS meets international standards CE, RoHS, UL and can be used with global voltage supplies. The sealless magnetically coupled pump ensures high durability and prevents leakages.

The HRS thermo chiller is ideal if space is scarce and save operation is important. They can be used worldwide, e.g. for laser cooling a laser, UV-lamps in drying plants, electronmicroskopes, digital X-ray machines, ultrasonic testsing systems, high-performance spindles, spark erosion, atomization devices, linear motor, packaging lines, vacuum pumps and many more applications. They are also suited for thermal control in glass bottle lockers, destillation, cooling of samples and reagents, or for short, anywhere in the industry where cooling or precise temperature control is required.

The thermo chillers of the series HRS by SMC Pneumatic for heat extraction of cooling water combine lightweight compactness and highly precise cooling capacity. HRS meets international standards CE, RoHS, UL and can be used with global voltage supplies.

Thanks to the build in mechanical pump and the small tank the HRS is compact and lightweighted. The chiller can be operated even during winter months without additional heating, as the compressor´s discharge gas can be used for heating, to keep the fluid well tempered. Easy maintenance with userfriendly extended controlling functions like self-diagnosis and error display as well as a communication function for the remote control and status report.

The temperature controller are suited for any application where a fluid with constant temperature is fed to a machine. The field of application includes the manufacturing-, chemical- and food industry. The HRS series controls the temperature of printing- or cleaning machines, tap water cooling towers and high-frequency induction systems as well as electric-arc- or resistance-welding machines.

The temperature controller of the series HRSH by SMC Pneumatic for heat extraction of cooling water is highly energy-efficient. Thanks to the triple inverter, the frequency of the compressor, pump and fan is set load-dependent, thus energy saving up to 53% in comparison to the non-inverter device. The sealless magnetically coupled pump ensures high durability and prevents leakages.

The temperature controller of the series HRSH by SMC Pneumatic for heat extraction of cooling water is highly energy-efficient. Thanks to the triple inverter, the frequency of the compressor, pump and fan is set load-dependent, thus energy saving up to 53% in comparison to the non-inverter device. The sealless magnetically coupled pump ensures high durability and prevents leakages.

The HRSH series is available either air- or water-cooled and has a cooling capacity of 10 to 28 kW as well as a temperature stability of ± 0,1°C. The chiller can be operated even during winter months without additional heating, as the compressor´s discharge gas can be used for heating to keep the fluid well tempered.

The temperature controllers are suited for any application where a fluid with constant temperature is fed to a machine. The field of application includes the manufacturing, chemical and food industry. The HRSH series control the temperature of printing- or cleaning machines, tap water cooling towers and high-frequency induction systems as well as electric-arc- or resistance-welding machines.

Catalog

Product configuration

Selection guide for cooling and temperature control units

Ask SMC

The thermo chillers of the HRS-R series from SMC for cooling cooling water combine lightweight compactness with high and precise cooling performance. HRS-R chillers are protected against dust and splash water. They meet the international standards CE and RoHS. They can be operated on all current electricity networks worldwide. The sealless pump with magnetic coupling offers freedom from leaks and a long service life. The housing is made of metal and can optionally be made of stainless steel.

The thermo chillers of the HRS-R series from SMC for cooling cooling water combine lightweight compactness with high and precise cooling performance. HRS-R chillers are protected against dust and splash water. They meet the international standards CE and RoHS. They can be operated on all current electricity networks worldwide. The sealless pump with magnetic coupling offers freedom from leaks and a long service life. The housing is made of metal and can optionally be made of stainless steel.

The HRS-R Thermo Chillers are ideal in tight spaces and when safe operation is important. Thanks to the special encapsulation of the electronics, they can be used in a dusty environment. They don’t mind splashing water either. They can be used worldwide. The chillers can be found in many applications. Examples are the cooling of lasers, electron microscopes or digital X-ray devices. In industry, temperature control units are used for high-performance spindles, linear motors, packaging lines or vacuum pumps. In short, it can be used wherever cooling in industry is required and the temperature has to be maintained exactly.

The temperature control unit of the HRZ-F series from SMC has been specially developed for applications in the semiconductor industry and has industry-standard approvals. It is used to control the temperature of processes and can be used with various media. The heat exchanger and the main tank are placed in the sub-tank, which makes the chiller practically leak-free. A leakage sensor is also installed so that a high level of safety is assured.

The HRW series is available in a water-cooled version. It has a cooling capacity of 2.0 to 30.0kW and a heating capacity of up to 6.5kW – depending on the model selected. The pump is controlled by an inverter, which reduces power consumption by up to 89%. This chiller does not have a refrigeration circuit, which means that no F-gases are used.

The temperatures of the circulating medium can be set from 20 ° C to 90 ° C. The temperature stability is ± 0.3 ° C. The temperature control devices are suitable for all applications in which a medium with a constant temperature is to be fed to a device. The HRW series cools and temperature controls a wide variety of applications in the semiconductor industry, such as etching or cleaning wafers.

The temperature control unit of the HRZ-F series from SMC has been specially developed for applications in the semiconductor industry and has industry-standard approvals. It is used to control the temperature of processes and can be used with various media. The heat exchanger and the main tank are placed in the sub-tank, which makes the chiller practically leak-free. A leakage sensor is also installed so that a high level of safety is assured.

The adjustable temperatures of the circulating medium can, depending on the option selected, be in the low temperature range up to -20 ° C or in the high temperature range up to + 90 ° C. But there is also a version that can cover the entire temperature range.

The HRZ-F series is available in a water-cooled version. It has a cooling capacity of 2.0 to 10.0 kW and a heating capacity of up to 6.5 kW – depending on the model selected. The pump and the DC compressor are controlled by inverters, which reduces the power consumption by up to 65%.

The temperature stability is ± 0.1°C. The temperature control devices are suitable for all applications in which a medium with a constant temperature is to be fed to a device. The HRZ-F series cools and temperature controls a wide variety of applications in the semiconductor industry, such as etching or cleaning wafers.

Our Thermo-con temperature control units are free of refrigerants due to the use of Peltier elements and are the ideal solution to ensure high precision temperature stability between ±0.01 to ±0.03 ºC of circulating media.

The units are available in air-cooled as well as water-cooled versions and offer excellent cooling performance from 140 W to 1,200 W. Reliable design and low-vibration construction make the refrigerant-free cooling and temperature control unit a highly reliable device. In addition to excellent documentation, SMC as a global partner offers a worldwide service network.

Air or water cooled version

Air or water cooled version

The Thermo-con series HED allowes users to directly control the temperature of chemicals and high purity fluids. Applications are for example: temperature control of chemical tanks, cleaning devices, coating machines, wet etching equipment, etc. The use of PFA as medium contacting material prevents the contamination with metal ions.

A specially developed heat exchanger, which is custom fitted to the Peltier elements, results in a compact design and low weight.

In order to reach constant temperatures with precise limit values SMC developed Peltier element powered thermal baths. Industrial processes that have those requirements are for example: temperature control of source gas for MOCVD or diffusion furnances, high viscosity chemicals and fluids or analysis and conductivity measure instruments.

The lastest addition to our thermal baths is the series INR-244.  The rectangular immersion bath has a capacity of up to 39 litres and has a Peltier element, thus there is no need for any refrigerant. Particularly precise and with little vibration the series is perfect for usage in quiet surroundings and is very easily handled and maintened.

The rectangular immersion bath has a capacity of up to 39 litres and has a Peltier element, thus there is no need for any refrigerant. Particularly precise and with little vibration the series is perfect for usage in quiet surroundings and is very easily handled and maintened.

The device can either be air- or water-cooled, has a temperature control range of 0° to 60° C while maintaining a stability of ±0,02 °C. The built in circulation pump optimises the temperature distribution within the immersion bath. Thanks to the compact and light design, the series INR-244 can be used in small spaces and is suitable for all types of laboratories, for example in the field of medicine, pharmacy, biotechnology, electronics and semiconductor industry.

SMC offers temperature controller for a variety of utilisations: from highly precise thermal applications to complete solutions (thermal controller to application) to cooling water distribution and observation of machine cooling.

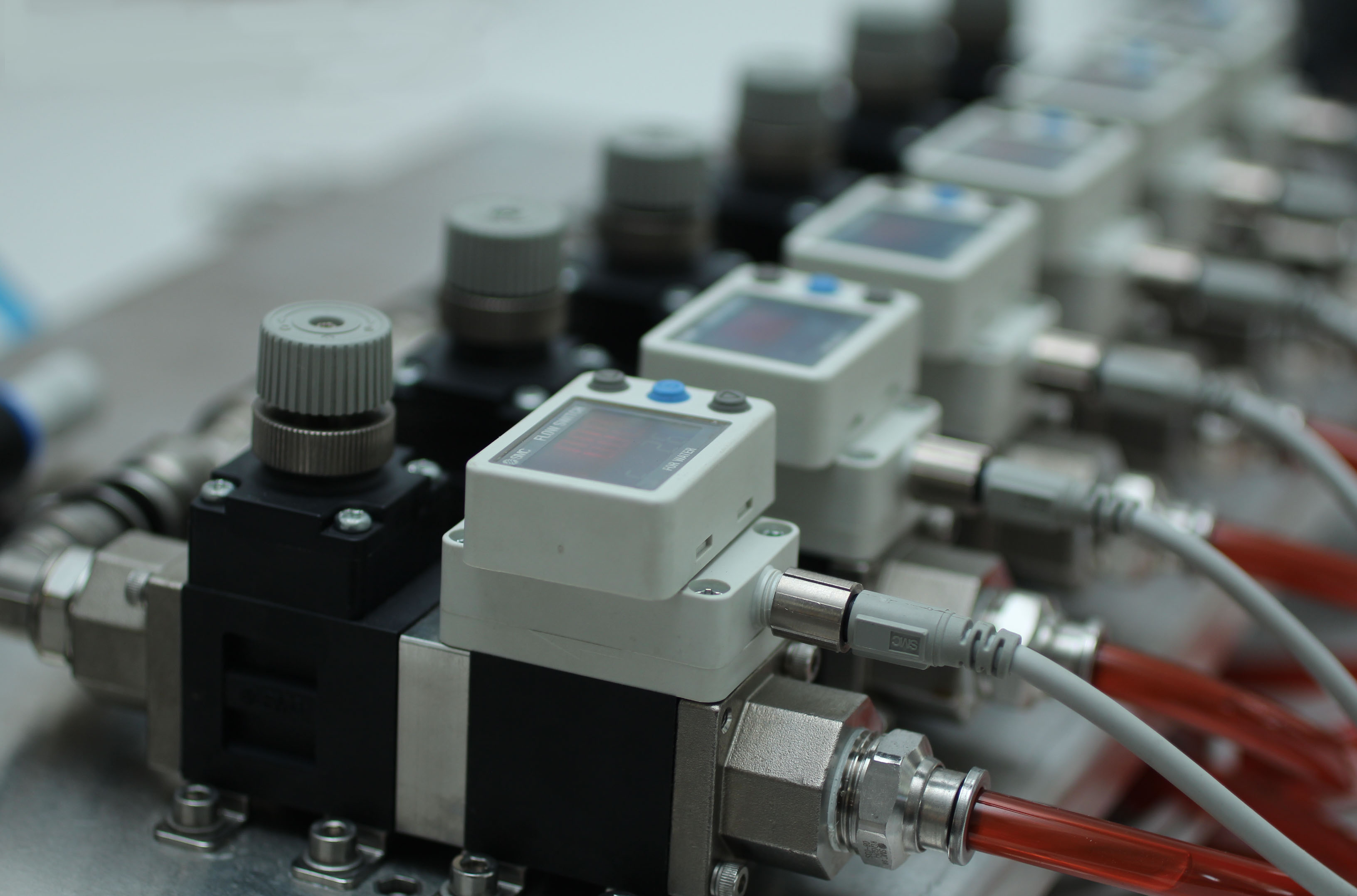

For applications including more than one heat source the chillers cooling water circuit has to be split up into parts. In order to achieve that SMC components like fittings, tubes, pressure and flow sensors are combined to create a water valve panel to measure the relevant process variables (pressure, flow and temperature). As a result every single circuit can be monitored to detect and identify unwanted process changes (e.g.: heat exchanger contaminations, leakage, etc…) as soon as possible.

Filters are used to extract particles from the circulation medium and to prevent total system failure caused by contamination.

In our product portfolio you can find:

You can find more information at www.smc.at.

SMC offers numerous products for process cooling in the industrial field and the high-end sector. The product range stretches from fittings, tubes, filter, pressure and flow montoring of the cooling circuit and temperature controller for highly precise thermal applications to complete solutions (cooling water distribution) for machine cooling monitoring.

The product range includes energy-saving thermo-chillers with refrigeration compressors and Thermo-con with Peltier elements for high-precision, vibration-free temperature control applications. Two different types of cooling (air and water-cooled) are available.

The SMC portfolio is rounded off by a number of innovative developments, such as Leakage and maintenance-free magnetically coupled pumps, two analogue controlled expansion valves for cooling and heating, inverter technology with speed-controlled refrigeration compressor, pump, fan, chemical thermocon with PFA heat exchanger for direct temperature control of chemicals, high-precision thermoelectric water baths for CVD (chemical vapor deposition) Processes and analysis.

Thanks to our years of experience we have complete solutions for anything from thermal chillers to valves tothermoelectric bath. Everything from one provider for any challenge - no matter how specific your wishes are.

Request information

Service is important to us! We have any and all solutions and designs custom fitted to your wishes and desires. Get on board and lay your trust in us, like many of our customers have been doing for years.

Contact us!

With the right choice and size, a cooling and temperature control unit improves the quality of the end product, protects valuable process equipment and reduces costs.

In three simple steps, we will guide you to the right SMC cooling and temperature control unit, for guaranteed efficiency and best performance.

Selection guide