Lasers stand for the highest precision, in industry as well as in medicine. Cooling devices that ensure constant temperatures during lasering have to work just as precisely. Laser temperature control from SMC offers stability, proven quality and global support.

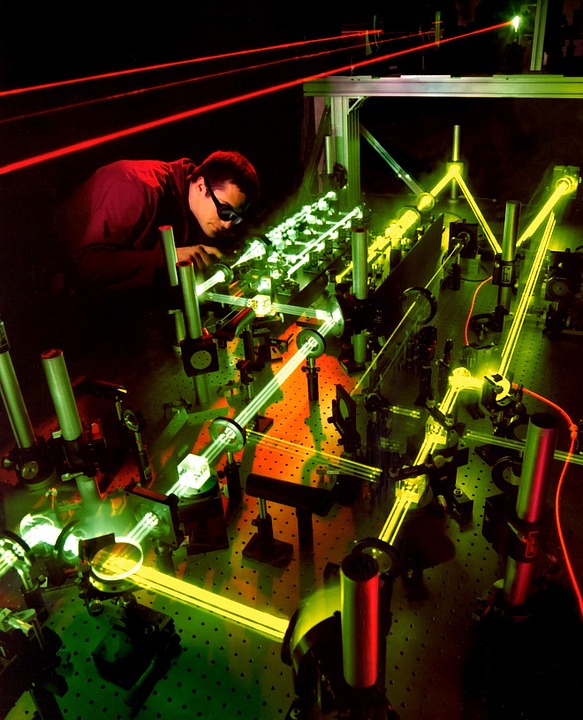

Heat is generated when lasering. Even if the laser beam itself is temperature neutral – the movement of tiny particles generates heat all around. This begins in the laser device itself, where the laser beam is guided through various, precisely adjusted optical lenses.

A thermal expansion of the base plate would change the alignment of the optical components. The laser could no longer work exactly. Cooling or temperature control is an important part of any laser process.

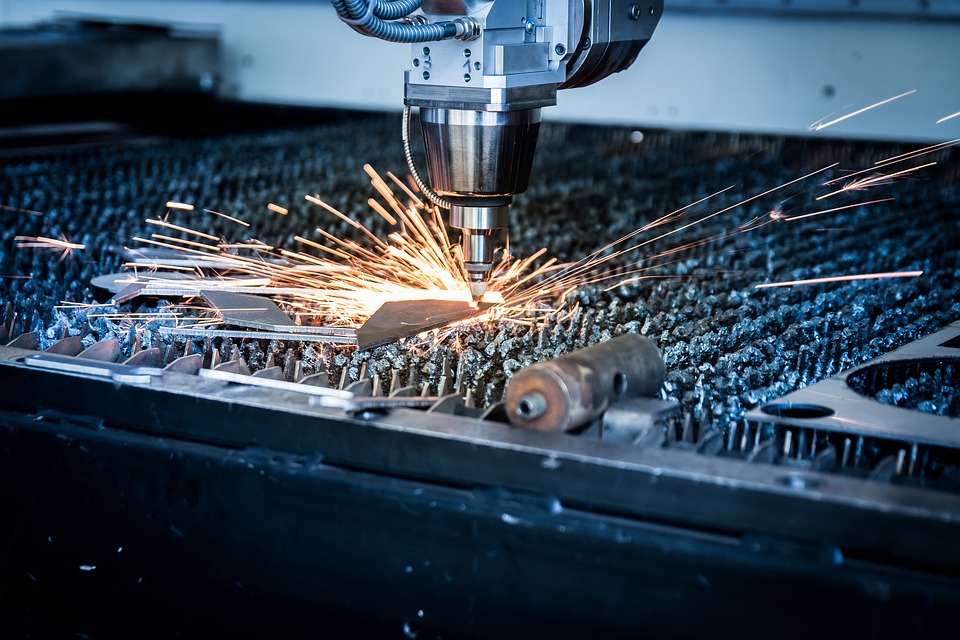

Lasers in industry and medicine

Laser devices are used in many areas today. They drill, cut, weld, label, engrave and treat surfaces according to special requirements. In industry, lasers are used wherever machining reaches its limits. Fiber or gas lasers are particularly common here.

Diode lasers are used in medicine. So-called ultrashort pulse lasers do not emit permanent light, but set ultrashort light pulses in the femtosecond range. Because the individual impulses are only so short, they can be dosed much higher without causing damage. This is important, for example, in eye surgery or for micromachining in the semiconductor industry.

Laser temperature control from SMC Stable laser power, sensitive materials and longer service life of the devices

Laser temperature control from SMC Stable laser power, sensitive materials and longer service life of the devices

“Laser” is a short word made up of the first letters of “Light Amplification by Stimulated Emission of Radiation”. So it’s about amplifying light through intensified radiation.

Laser temperature control is also about the stability of the laser power. Because the wavelength of the laser depends on the temperature.

Stable temperature conditions extend the life of the sensitive laser devices, the laser diodes and the laser generator. Exact temperature control also increases the up-time, which means it prevents failures and ensures stable availability.

Just think of laser eye surgery. The laser may only act on the sensitive tissue to the extent that the cornea is to be removed. But processing sensitive components also requires precision. The smallest components must fit exactly, the edges and the surrounding material must not change.

Laser temperature control from SMC

Temperature control units from SMC were developed for use in sensitive environments. Thanks to their flexibility, our chillers adapt to a wide variety of requirements. For example, installation in standardized 19-inch racks is possible without any problems.

SMC devices are suitable for different voltages and frequency ranges and can therefore be used worldwide. Customers around the world appreciate our global support.

Complete solutions for every requirement

Thanks to the wide range of products, SMC can offer complete solutions for process optimization. In addition to temperature control, this includes cooling water distribution, flow monitoring, ensuring the cooling function and early detection of process changes. This guarantees our customers process reliability and productivity.

Process quality and precision are a matter of course at SMC. Our years of experience in high-end environments guarantee components that meet the highest demands.

Communication for Industry 4.0

Digital inputs and outputs as well as serial communication allow connection to the most modern industrial environments.

Whether you want to address our chillers via your control system or have control messages read out via the existing system – with SMC you are prepared for Industry 4.0.

DE

DE CZ

CZ HU

HU PL

PL SI

SI