Liquids are valuable in analysis technology. Often dangerous in the semiconductor industry. Dripping valves are out of place here. SMC has developed reliable suck back valves that can be dosed particularly precisely. Individual drops have no chance of escaping.

It is similar to a faucet: If liquid flows through an outlet, one last drop still remains after turning it off. Often there is also repeated dripping.

The last drop can do a lot

This can have serious consequences in the semiconductor industry. Not only that you are dealing with aggressive liquids that are harmful even in the smallest droplets. Sensitive electronic components can be damaged by the pressure of an uncontrolled falling drop.

But even in medical analysis processes, not a single drop is allowed to become independent. During the analysis of blood or urine samples, additive test liquids must of course be supplied in absolutely exact quantities. Any deviation can affect the result. And with particularly small amounts of liquid, half the sample can be lost through a wasted drop.

Back suction valve prevents dripping

A so-called suck-back valve ensures that residual liquid is sucked back before it can escape. This prevents dripping. Such valves are state of the art in the semiconductor industry and are also often used in medical technology.

But back-suction valves from SMC can do even more. As a specialist in automation solutions and an experienced partner to industry, SMC can offer a wide range of components for valve and control technology – and combine them perfectly.

Precise dosing through combined valve unit

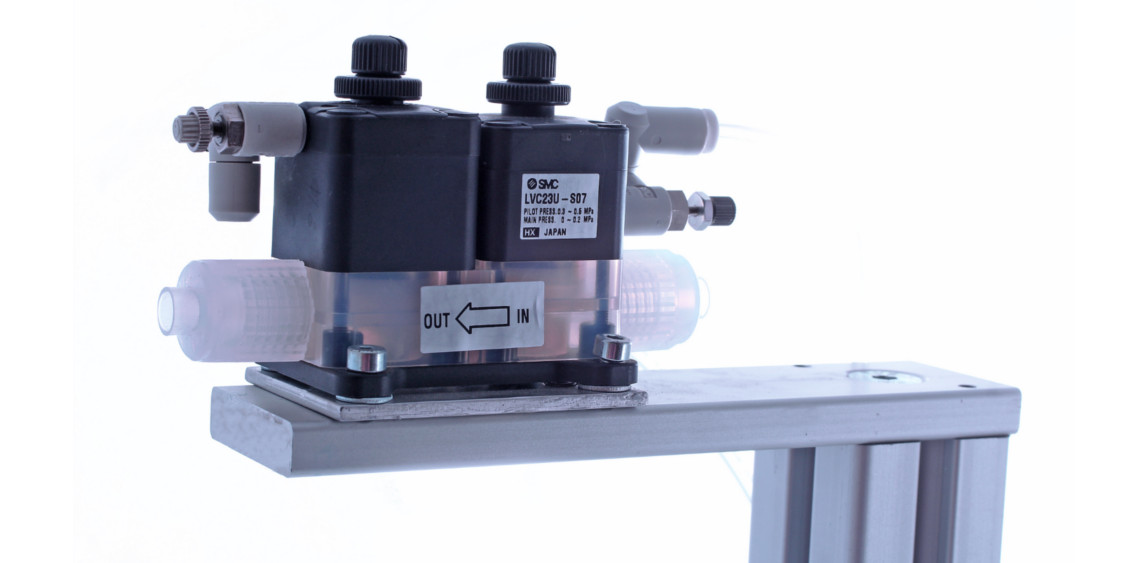

The valve unit from SMC consists of the actual suck back valve and an on / off valve. This combination is unique and allows a much more precise dosage than is possible with conventional suck back valves.

Not only can the back suction and flow rate be set exactly. The opening and closing speed of the valves can also be precisely regulated using special throttles. This prevents impacts from occurring in the medium.

Perfect processes right through to the end

The exact settings guarantee you a permanently closed liquid column after switching off. The media column is interrupted in a controlled manner and nothing is lost. This is how you achieve perfect processes right through to the end of the dispensing process.

Would you like to know more about combined back suction valves from SMC? Our experts will be pleased to advise you.

DE

DE CZ

CZ HU

HU PL

PL SI

SI