SMC ionizers of the IZS and IZT series protect electronic components such as chips in the semiconductor industry during production against electrostatic charging and the resulting defects. To do this, they capture and neutralize the electrostatic charge by producing positively and negatively charged ions and emitting them to the respective workpiece.

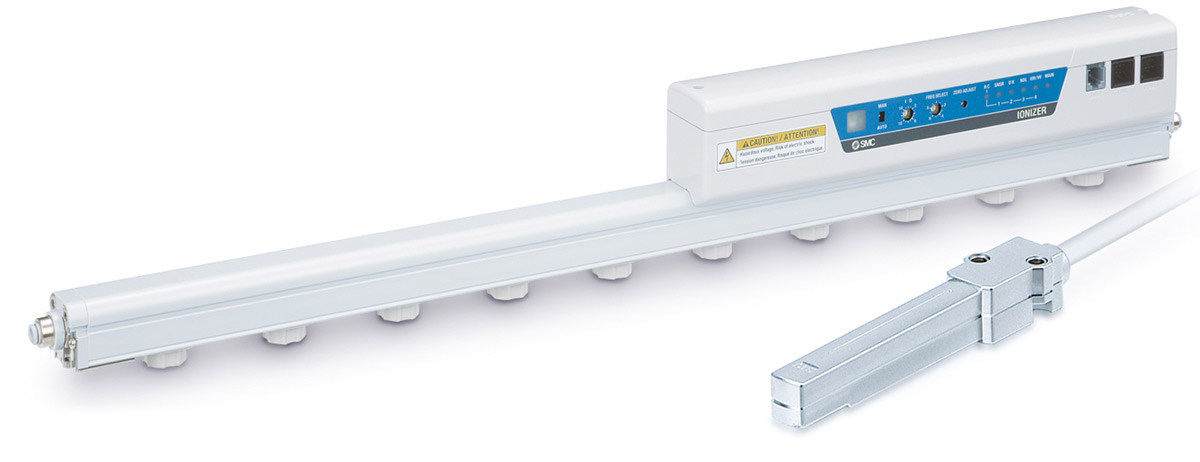

IZS series with integrated controller

Our IZS series (IZS40/41/42) are all-in-one devices with a height of approx. 10 cm: ionization, electronics and high-voltage units are all in one device.

Dual-AC ionizers (IZS42) reduce the potential amplitude on the workpiece. The simultaneous discharge of positive and negative ions ensures that both reach the workpiece evenly and thus the potential amplitude on the workpiece is reduced.

The IZS41 dissipates static electricity very quickly due the optional feedback sensor. The sensor detects the electrostatic charge of the object to be discharged, measures the charging voltage, and then emits ions of reverse polarity.

Our standard version IZS40 ionizer is very easy to control by just switching on the ionizer. The discharge time is 3.2 seconds (41% faster) when installed at long distances (1,000 mm).

IZT series with separate controller

In the IZT series, the ionization bar can be constructed separately from the electronic and high-voltage unit. The ionizing bar has a height of approx. 37 mm and is therefore well suited for narrow, built-in, and space-limited places in the system.

With this design, electromagnetic particles that can result from the electronic and high-voltage unit can also be minimized. This series is available with IO-Link (manufacturer-independent fieldbus connection to the PLC).

Our IZT series is available in bar version (IZT40/41/42) and nozzle version (IZT43). Ionizers with nozzles remove dust and discharge static electricity, for example from plastic bottles, by means of a blow-out pulse.

IZT series ionizers are available in dual-AC (see IZS series for details) and AC (IZT41+43) versions. In the AC version, positive and negative ion layers alternately reach the workpiece, which ensures the maintenance of a constant offset voltage.

The controller allows easy monitoring of the individual ionizers and can be used to control a maximum of 4 ionizers, whereby a mixed connection of bar and nozzle is possible. It quickly detects ionizer faults and monitors contamination of the electrode needles. Compressed air is blown off on their surface, which minimizes contamination of the emitters.

Areas of application of ionizers

- In semiconductor production when processing wafers for chip production.

- Prevents glass substrates from being damaged by static electricity produced when the substrate is lifted from the surface plate.

- Discharge of static electricity on printed circuit boards: Prevents fractures of components caused by discharges and adhesion of dust.

- For plastic and rubber workpieces: Prevents bottles from falling on the conveyor belt and dust deposits, for example, and improves the detachability of objects made of press molds.

Benefits for our customers

- Low potential amplitude of maximum 25 volts minimizes defects and unplanned downtimes

- High discharge speed (3.2 seconds at a distance of 1 meter) allows faster production

- Feedback sensor to optimize discharge speed

- IO-Link for manufacturer-independent fieldbus connection to the PLC

- space-saving (IZT series) and therefore ideally suited for installation in confined spaces (e.g. rotary presses)

- less waste

- Cost reduction

- higher production reliability

- durable solution

Would you like to learn more about our ionizing devices of the IZS and IZT series and their areas of application?

Get in touch with us – our team will be happy to answer your questions.

DE

DE CZ

CZ HU

HU PL

PL SI

SI