High vacuum – never heard of it, why do you need it? Here is an insight into the important technology of the (high) vacuum, without which a modern life as we know it today would not be possible.

What is (high) vacuum?

There is a pressure of 1013 mbar in our atmosphere – when the pressure is reduced in a system, we speak of a vacuum. But here too there are subdivisions into several print areas. The lower the pressure, the “higher” or “better” the vacuum becomes. A distinction is made between negative pressure (vacuum cleaning or vacuum packaging), rough vacuum (old light bulbs), fine vacuum (freeze-drying) and high vacuum (electron tubes, electron microscopes) to ultra-high vacuum.

The generation of high vacuum

Vacuum is created with pumps that are not actually pumps, but are only called this way. Strictly speaking, these are densities. This means that these pumps move air molecules that get into the pump out of the (vacuum) chamber. As a result, the pressure in the chamber becomes less and less. To generate high vacuum, you need a system that consists of two pumps: a backing pump and a so-called turbomolecular pump.

Special features of the high vacuum

An important term is the so-called mean free path. It describes the distance that a gas particle can travel on its way without colliding with other gas particles.

Let us remember – vacuum pumps are compressors, they can only transport molecules out of the chamber that get into the pump. When there is normal pressure, the air molecules collide very often because the mean free path is only approx. 68nm. For comparison: an average human hair is about 1000 times as thick. Since the molecules collide very often, even thin lines (e.g. 1/2 inch = 12.7mm) and small connections are flowed through quickly and well. This way, the molecules get to the pump quickly.

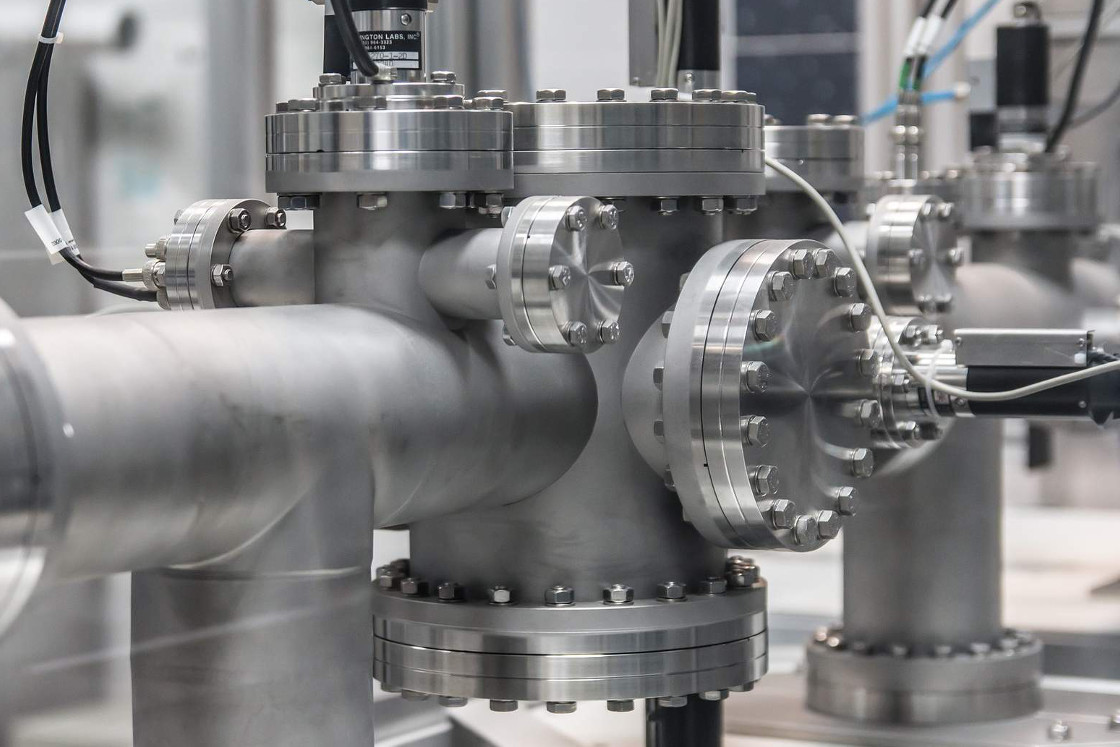

The further the pressure drops, the fewer molecules are in the chamber and the longer the mean free path. In a high vacuum, it is between 10 centimeters and one kilometer. For this reason, the molecules collide less and in order to get to the pump quickly, the connections to the valves must be very large (see sketch). That is why SMC offers sizes up to 160 mm nominal diameter (= inner diameter).

What do you need high vacuum for?

Products that are produced in a high vacuum can be found almost everywhere in our everyday life. We have summarized some examples for you here:

- Coatings: An important process that only works in a high vacuum is physical vapor deposition. It is used in the manufacture of microchips, CDs and DVDs. An extremely clean environment is important here, since particles are a big problem.

Further application examples: coating of tools, foils (food industry, glasses, cars, jewelry, …) - Electron microscope: Instead of a light beam, the electron microscope uses an electron beam. Since electrons are very small, they would be deflected by air molecules – so the microscope needs high vacuum to function.

- Leakage tests: refrigerators, air cooling, heat pumps, braking systems, airbags and much more. Many systems have to be checked for leaks, since leaks have devastating consequences for our safety, health or the environment. These leak tests can only be carried out in a high vacuum, where even the smallest leaks cannot be overlooked.

- Analytics: An example from analytics is the mass spectrometer. It measures the mass of atoms or molecules (atomic weight) after they are converted into the gas phase and ionized. If the pressure were too high, the ions would collide with air molecules and could not reach the detector. In addition, free ions and electrons could not be generated without a high vacuum and the life of the device would be drastically shortened.

Examples of use: Examination of substances in the body in medicine and criminal technology and in doping controls, analysis of environmental toxins, warfare agents and explosives and much more.

SMC high vacuum valves impress with their high quality and service life. They meet high sealing standards and are extremely corrosion-resistant. Here you will find all products for pneumatic, electromagnetic and manual drives.

DE

DE CZ

CZ HU

HU PL

PL SI

SI