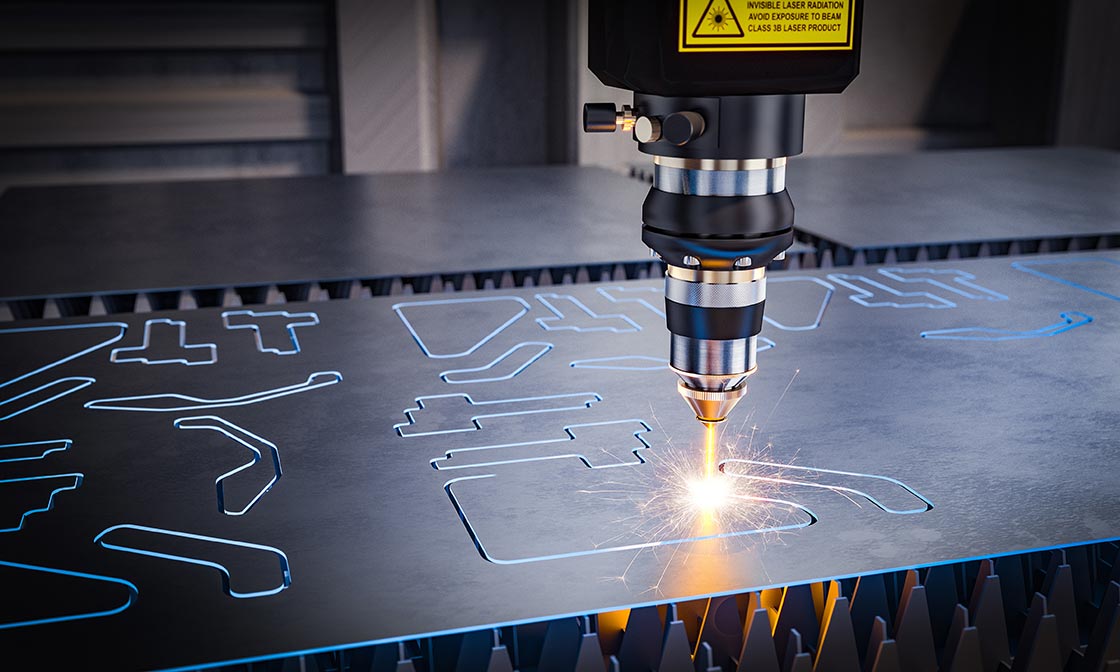

We developed the air-cooled dual loop chiller of the HRL series especially for industrial applications with high-power lasers. It ensures constant temperature of the cooling water. Such laser applications are cutting, welding, measuring, coating, sintering and stereolithography.

Since lasers generate heat, cooling is an important part of any laser process. Exact and stable temperature control extends the service life of the sensitive laser devices, prevents failures and ensures continuous availability. You can find more about laser temperature control in this link.

The fact that the chiller can operate two cooling circuits at the same time saves space – the dual loop chiller reduces the space required by around 22 percent compared to two individual devices.

At the same time, the temperature control unit saves a lot of energy. With a triple inverter, it adjusts the motor speed depending on the load. The chiller uses up to 34 percent less energy than non-inverter devices.

A sealless mechanical immersion pump also ensures that there is no leakage and reduces maintenance costs.

Versions of the HRL Dual Loop Chiller

The air-cooled temperature control unit of the HRL series is available in three versions with different cooling capacities: 10 kW, 20 kW and 27 kW, with 1 kW each reserved for the second circuit. The temperature stability is +/- 0.1 ° C or +/- 0.5 ° C.

High temperature accuracy and stability

The simultaneous control of the compressor, fan (both frequency-controlled) and the electronic expansion valves keep the temperature stable even with fluctuating heat loads (oscillator with stable load +/- 0.1 ° C and optical system +/- 0.5 ° C) .

Due to the power density, this high temperature accuracy ensures optimal energy yield and enables excellent focusing of the laser. The stable temperature contributes to low component wear, which in turn ensures a long service life.

To prevent the formation of condensation, the HRL Dual Loop Chiller does not allow you to set a lower temperature for channel 2 (optical system = laser head) than for channel 1 (oscillator = laser source). This means that incorrect settings are pretty much ruled out.

Saves space and saves time

With the Dual Loop Chiller from the HRL series, you not only save up to 22 percent floor space, but also benefit from the reduced cabling effort: You only need one power supply for the separate temperature control of two media circuits and therefore less work for the cabling.

Less energy consumption

In non-inverter devices, the speed depends on the mains frequency, which means that power is wasted. With our dual HRL industrial cooler, however, you save up to 34 percent energy. This is made possible by the built-in triple inverter, which controls the motor speed of the compressor, fan and pumps depending on the load of the user system.

In addition, our dual loop chiller heats the circulating fluid without an electrical heating element, thereby saving additional energy. Instead of the heating element, the process heat from the compressor is used by using the already heated refrigerant (gas).

Easy to use touch panel

The user-friendly touch panel enables various displays and settings: The status display provides information on temperatures and flow rates, for example; individual data can be entered using the numeric keyboard; the temperature profile of the circulating fluid can be traced via the display.

As soon as an alarm is triggered, the screen automatically changes to the information screen and shows codes and contents of the alarm.

If a component reaches the specified service life and needs to be replaced, a maintenance notice is given.

Further features and advantages of the HRL Dual Loop Chiller

There are three different operating modes of the circulating media pumps that you can select via the touch panel:

- Pressure control mode

- Flow control mode

- Pump operating frequency (rotation) control mode

In addition, both circuits use mechanical, sealless pumps. This saves you regular checks for leaks as well as the replacement of mechanical seals and reduces the overall maintenance effort.

The following are also included as standard:

- Integrated bypass (one bypass valve each for oscillator and optical system)

- Electrical conductivity control with DI filter and built-in solenoid valve for control, whereby you can freely set the specific electrical conductivity of the circulating medium using the touch panel

- Particle filter set to remove impurities from the circulating medium – thanks to a transparent container, contaminated elements can be easily identified and effectively protect your system from the ingress of foreign matter

- Transport rollers for moving as well as adjustable feet for fixing the cooler

Would you like to find out more about our HRL series dual loop chiller and its applications?

Get in touch with us – our team will be happy to answer your questions.

DE

DE CZ

CZ HU

HU PL

PL SI

SI