There are valves in almost all areas of industries and they usually have to be operated and automated pneumatically. Industrial valves control and regulate the flow of gases, steam or liquids in pipelines. If necessary, the valves also shut off the flow.

There are valves in almost all areas of industries and they usually have to be operated and automated pneumatically. Industrial valves control and regulate the flow of gases, steam or liquids in pipelines. If necessary, the valves also shut off the flow.

Components for automated industrial valves

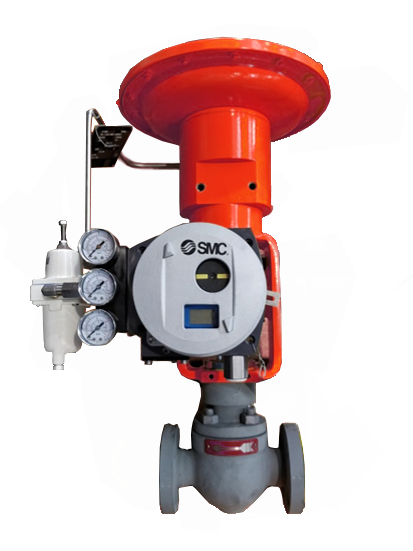

In order to be able to do all of this automatically, industrial valves require the following three components:

- Actuator

- Compressed air supply

- Positioner

An actuator is a drive unit used to control a valve. This happens by converting an electrical signal into mechanical movements and thus actively intervening in the controlled process. In process automation, pneumatic or hydraulic drives are often used for this.

In order to be able to control large valves safely and easily, compressed air is required, and a positioner is necessary to regulate the compressed air to the cylinder.

Positioners are electrical-pneumatic control units that adjust pneumatic cylinders precisely in any position – they control the compressed air to the actuator. The positioner is connected to the drive mechanically or with a remote sensor and converts the electrical or pneumatic input signal into a corresponding output signal that determines the target position. The actual position is determined by means of position feedback and any difference of the actual position to the target position is adjusted accordingly.

Complete solutions and one-stop-shop for valve automation

What sounds like a lot of effort in procurement and solution development is actually quite simple and you benefit in two ways:

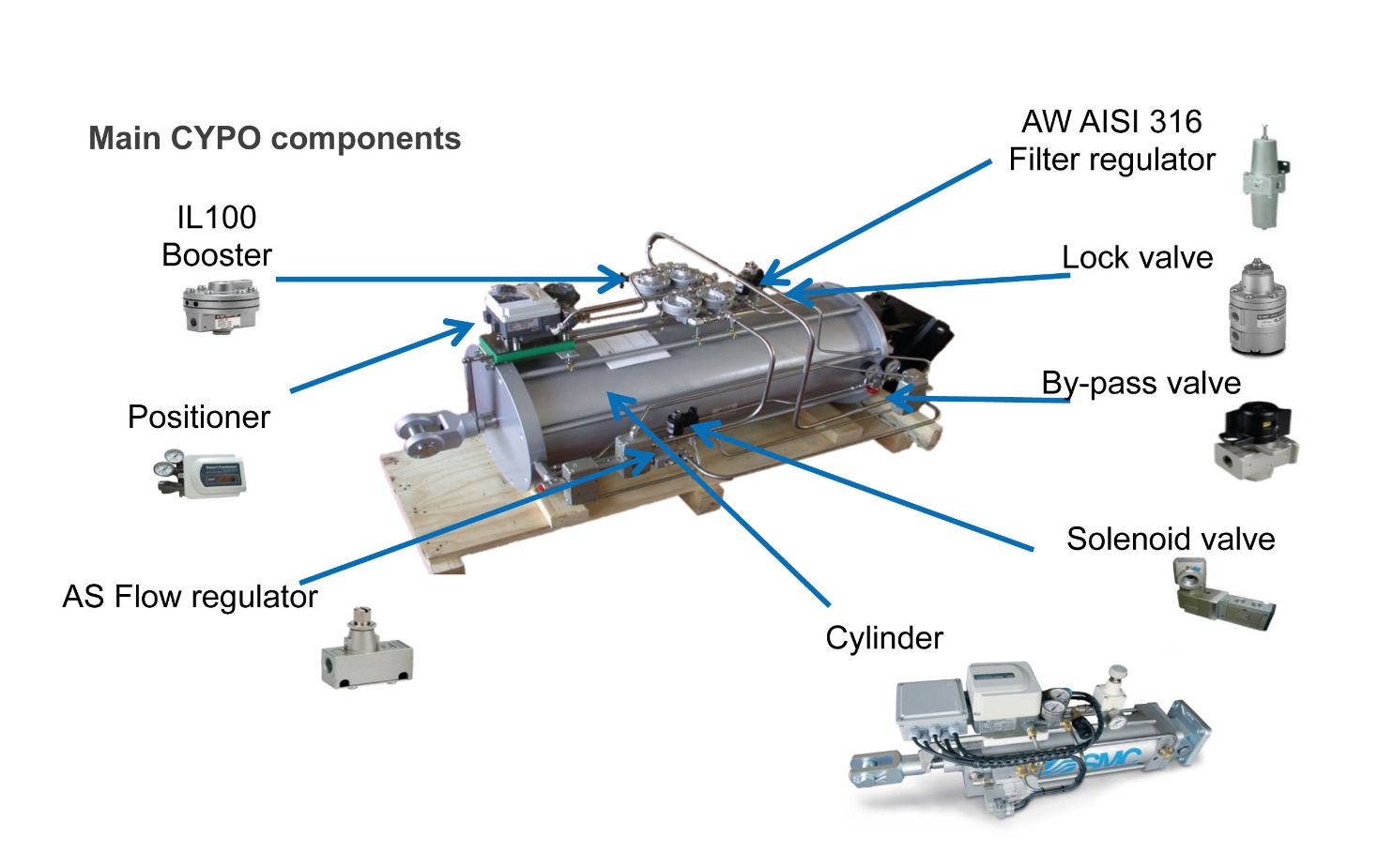

We offer you all-in-one solutions for your valve automation and develop individual solutions for your applications according to your wishes and requirements with high-quality SMC products.

We offer you all-in-one solutions for your valve automation and develop individual solutions for your applications according to your wishes and requirements with high-quality SMC products.

As a one-stop shop, we have all the necessary components available, from positioners and special valves to complete compressed air supplies including accessories such as one-touch fittings made of stainless steel.

Where is valve automation used?

Valve automation makes sense for users who have to control large valves for gases or liquids. These include

- chemical industry

- water supply, water and wastewater treatment

- sewage treatment plants

- paper industry

- thermal power stations

Integrators such as system builders, mechanics, metal workers, engineers or valve specialists often take care of the installation of the automated industrial valves at the user’s facility.

You can find examples of our solutions for valve automation on our YouTube channel.

If you are planning a new system or have problems with your existing valves, we can recommend various integrators and answer your questions – just contact us.

DE

DE CZ

CZ HU

HU PL

PL SI

SI