Pneumatic booster valves (also called booster relays, volume flow amplifier or volume booster) increase the speed of applications and are used in pneumatic systems to amplify the flow rates of compressed air.

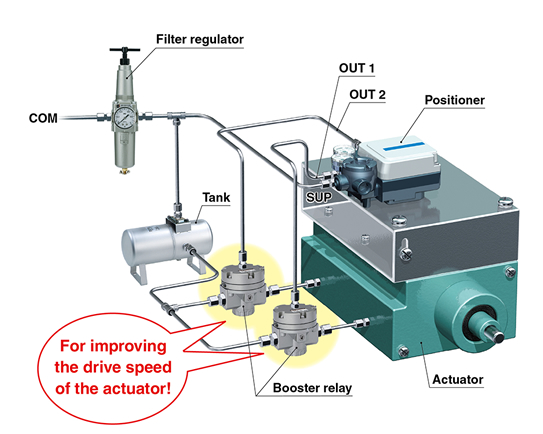

A booster valve works similarly to an electrical relay and has three connections: supply pressure, output and signal. The signal pressure e.g. provided by a positioner to the signal port of the booster valve, leaves the output connection of the booster valve with a significantly higher flowrate (L / min), i.e. it has a much higher volume flow. If the positioner can deliver a maximum flow rate of e.g. 200 L / min compressed air, the booster valve can provide more than 1,400 L / min.

You will find a very good introduction how Booster Valves work in our YouTube video.

When are Booster Valves used?

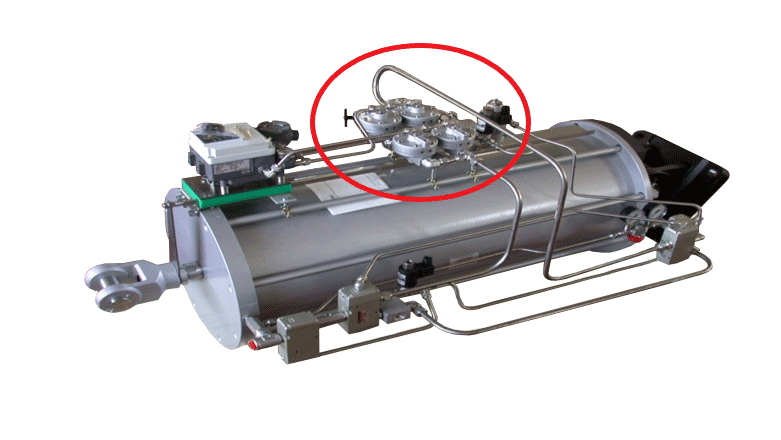

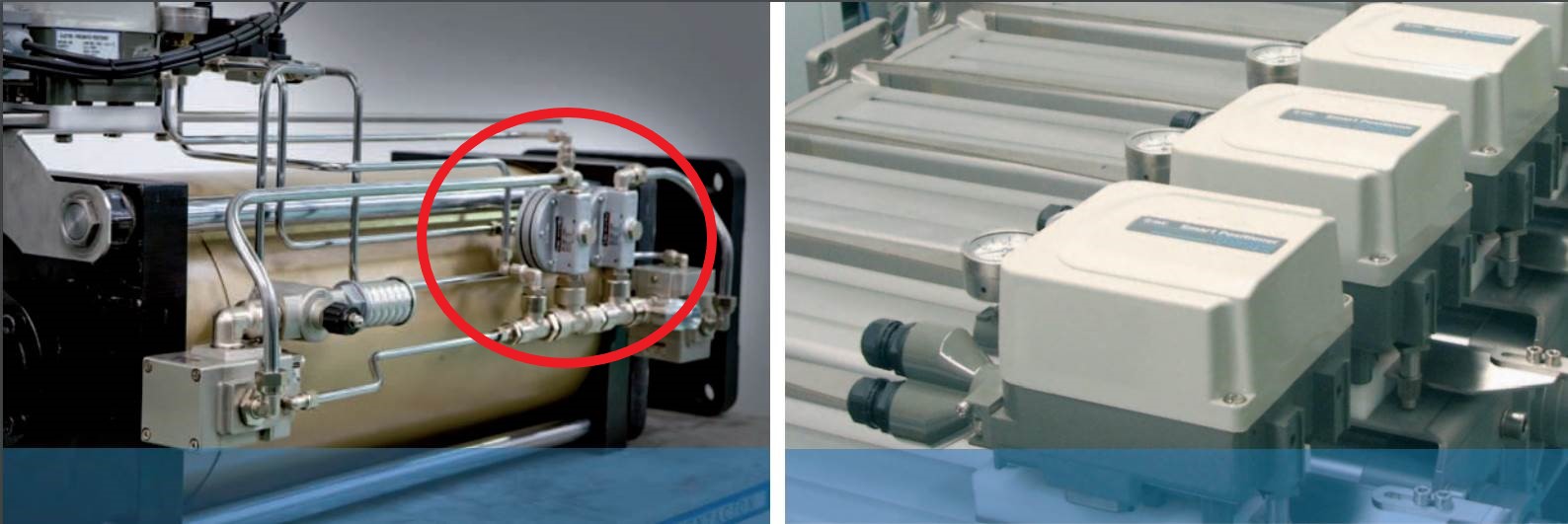

The usage of booster valves is necessary, if- the compressed air line between the positioner (control, pressure generation) and the pneumatic drive (actuator, consumer) is long – e.g. if the positioner is mounted far away from the cylinder

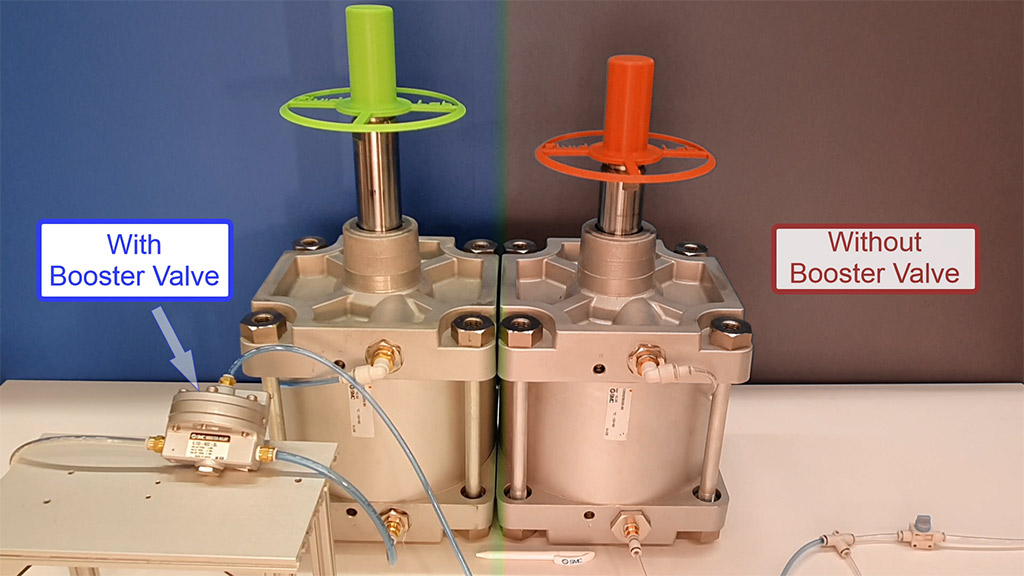

- large actuators are to be driven quickly

- components with large air consumption are used

- and in the field of valve automation, especially with large industrial valves, in order to accelerate CYPOs (combination of CYlinder and POSitioner).

How a Booster Valve works in detail

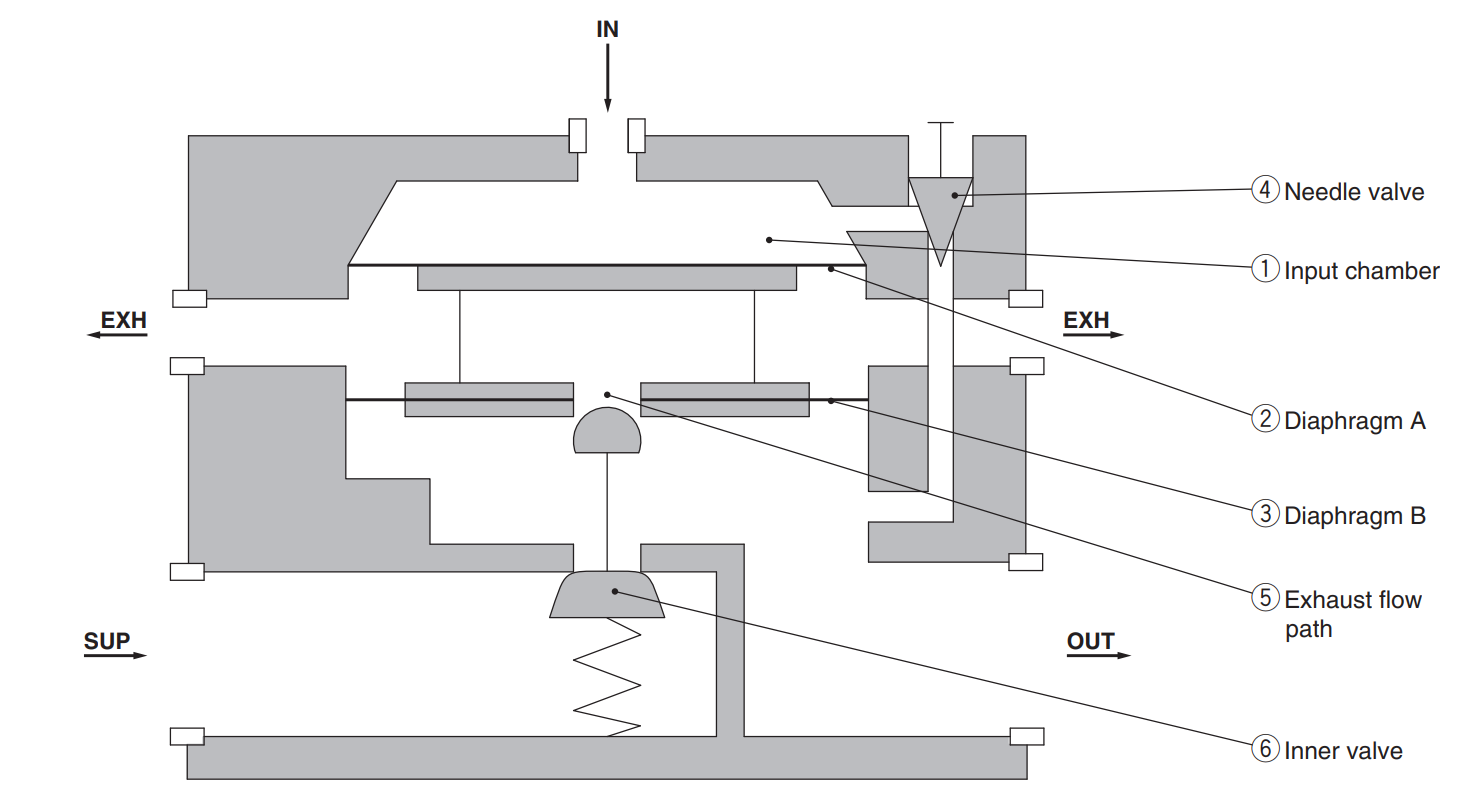

The signal pressure enters the input chamber and a force creates pressure on diaphragm A in a downward direction on diaphragm B. When the force of the input chamber exceeds the force of diaphragm B, the inner valve opens and air flows out of the outlet. With signal pressure dropings the supply valve closes and the exhaust flow path opens so that the outlet pressure can be vented to the atmosphere. The inlet chamber and the outlet are connected via a needle valve. Signal pressure and outlet pressure are precisely matched to one another in a ratio of 1: 1. This is ensured by the factory presetting. The above function enables a low flow signal to produce a high flow output with a pressure ratio of 1:1 between the signal pressure and the output pressure.

Features of Booster Valves

Features of Booster Valves

- Volume flow boosters contribute significantly to increase the actuating speed.

- Booster valves are robust, easy to use and very affordable.

- The air consumption is 3 L / min or less.

- Suitable for high (-5 to 100° Celsius) and low temperatures (-30 to 60° Celsius).

- as copper free or stainless steel available.

Range of applications of booster relays

Range of applications of booster relays

If you want to adjust

- flowrates of fluids with large pneumatic control valves (like wastewater, freshwater, cooling water, liquid chemicals, oil, steam, ….),

- large flowrates of gases with jalousie or butterfly valves (for exhaust gas / air, fresh air, smoke, etc.) or

- the transport route of fine-grained solids (cement, gravel, ore, grain, chemicals, …) with CYPOs

You want to know more about possible applications and the function of booster valves?

Contact us – our team is happy to answer all your questions and advise you on your individual requirements.

DE

DE CZ

CZ HU

HU PL

PL SI

SI