Usually, the standard pneumatic cylinders can only move to two positions: they are either fully retracted or fully extended.

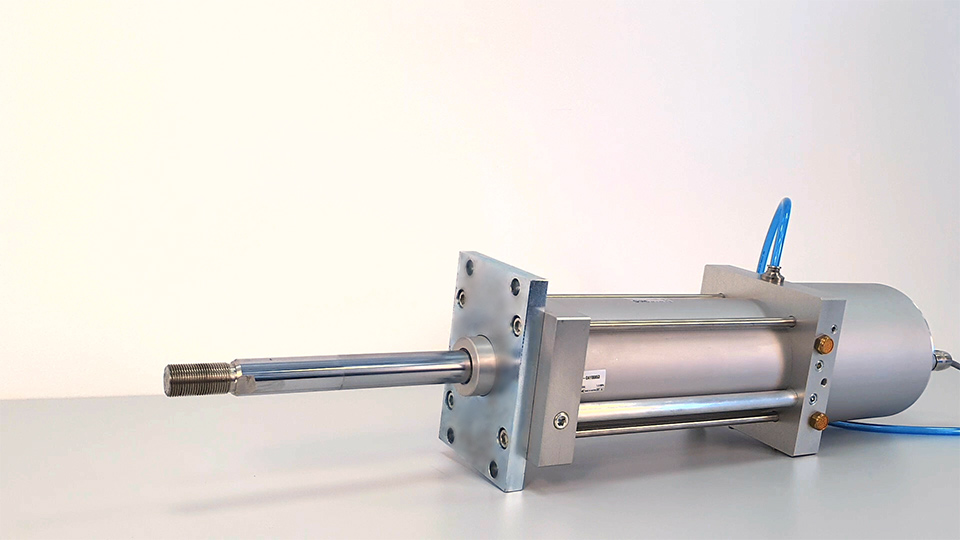

Thanks to a built-in positioner, our SMC Air Servo Cylinder IN-777 can be precisely adjusted to any position.

Applications

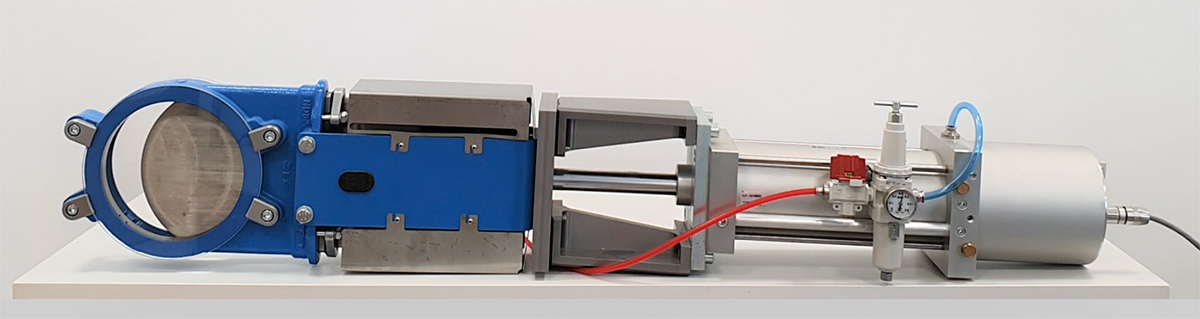

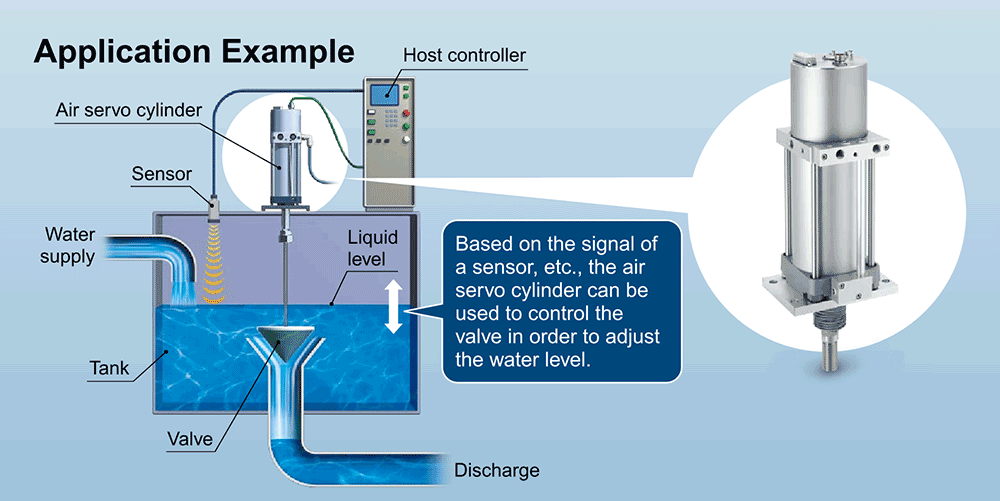

The Air Servo Cylinder IN-777 can be used for dart valves of flotation cells and for all other applications with linear movement e.g., as drive / actuator for industrial valves like butterfly valves, knife gate valves, diverter valves, jalousie valves, dampers, Dapó valves, etc.

Dart valves are connected to air servo cylinders with rods and adjust the water level in tank or flotation cells.

Flotation is used to separate mixtures of materials in many industries like

- mining industry in mineral processing for separating minerals from gangue by taking advantage of differences in their hydrophobicity

- in industrial wastewater treatment, where it removes fats, oil, grease and suspended solids from wastewater.

- in paper recycling to recover recycled paper

.

Advantages and properties of pneumatic Air Servo Cylinder IN-777

The all-in-one solution of our IN-777 pneumatic positioning system has numerous advantages:

- fast response time and high position accuracy of ± 0,5 mm

- easy calibration of end positions

- capable of air cylinder multipoint positioning and control

- simple maintenance due to unitization:

- for all cylinders the replacement parts are unified

- valve unit, pilot valve, controller assembly, seal kit, etc., are easily replaceable

- after replacement you can keep your settings

- easy initial settings – after input of an I/O signal to move the rod forward set the rod stop position to 20 mA (or 4 mA)

- 10 different speed settings available

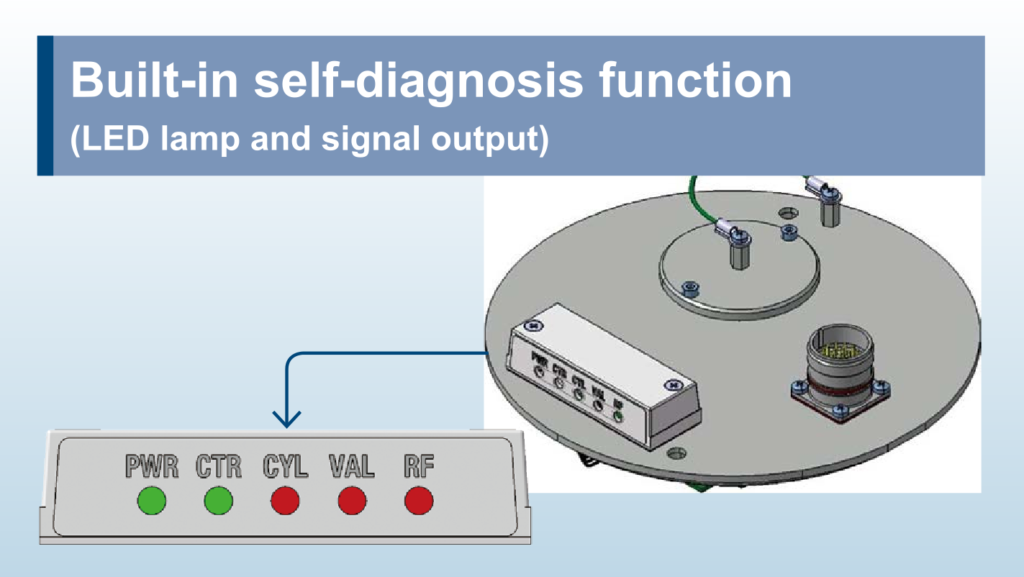

- Built-in self-diagnostic function via LEDs (power supply status, controller status, cylinder position sensor error, valve error, rod friction error) and signal output

- Emergency stop of the piston when the air or power supply is cut

- Fail-safe ports (if the pressurized air supply or power supply is cut, air from the emergency tank can be supplied via the FA/FB port in order to allow for the manual operation of the air cylinder rod)

- Easy maintenance and fast replacement of positioner unit.

You want to know how fast it can be done? Watch the video on our YouTube channel.

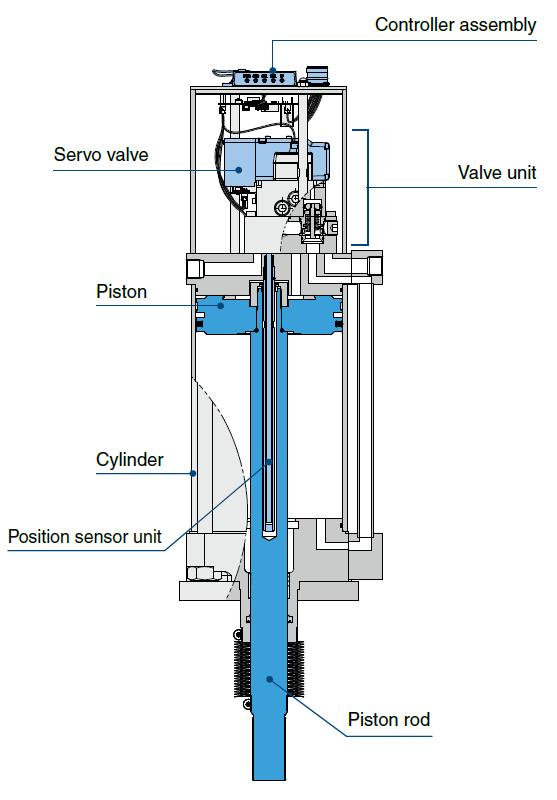

Working principle

The internal position sensor of the air cylinder transmits the current position of the piston rod to the controller. The controller sends a command signal to the servo valves according to the target position signal sent from the host controller. According to the command signal sent from the controller, the servo valves control the compressed air to move the piston rod forwards or backwards, or to stop it at the target position.

The opening and closing of the shutoff valve are controlled by the pilot valve connected to the controller.

Two air-operated shutoff valves (head side and rod side) are mounted along the air passage between the servo valves and the air cylinder. During an emergency stop (air or power supply cutoff, emergency stop signal input, etc.), the shutoff valves are closing, and the air cylinder operation stops.

Operation modes

The Air Servo Cylinder IN-777 can operate in different modes:

- target position (controlled by 4 – 20 mA)

- manual mode – the rod moves according to the signal input by the master controller.

- calibration modes – automatic (default) or manual

- no signal operation – if signal is 4 mA or less the rod will move to a predetermined position and then stop.

You want to know more about our air servo cylinder IN-777 and its applications?

Contact us – our team is happy to answer all your questions.

DE

DE CZ

CZ HU

HU PL

PL SI

SI