A positioner converts the electrical or pneumatic input signal into a corresponding output signal that determines the setpoint position. The position feedback is characteristic for a positioner: It is used to determine the actual position and readjusts a possible difference if necessary.

Our positioners work according to the nozzle/flapper system principle: An air nozzle blows compressed air onto a flapper. The flapper then moves or changes the distance – depending on the position of the valve -and thus changes the back pressure in the system until the setpoint of the value is reached and equilibrium prevails.

Where are positioners used?

Positioners are found wherever the flow of liquids or gases in pipelines has to be controlled – usually in conjunction with control valves, but also other industrial valves such as ball valves, segment valves, butterfly valves and gate valves with pneumatic actuators. Positioners are also needed to control steam in pipelines, which is used to heat processes or transport energy in power plants.

What advantage do positioners bring?

When processes are automated and optimized, precisely defined flow rates are often required e.g. an industrial valve with a pneumatic actuator can be used for this purpose. However, such an actuator has the limitation that it can only open or close fully.

An additional positioner, on the other hand, allows you to control the actuator to any intermediate position – so you can precisely adjust your cylinder. This allows you to optimize the efficiency of the system and save valuable resources at the same time.

Positioner types

For single and double acting actuators

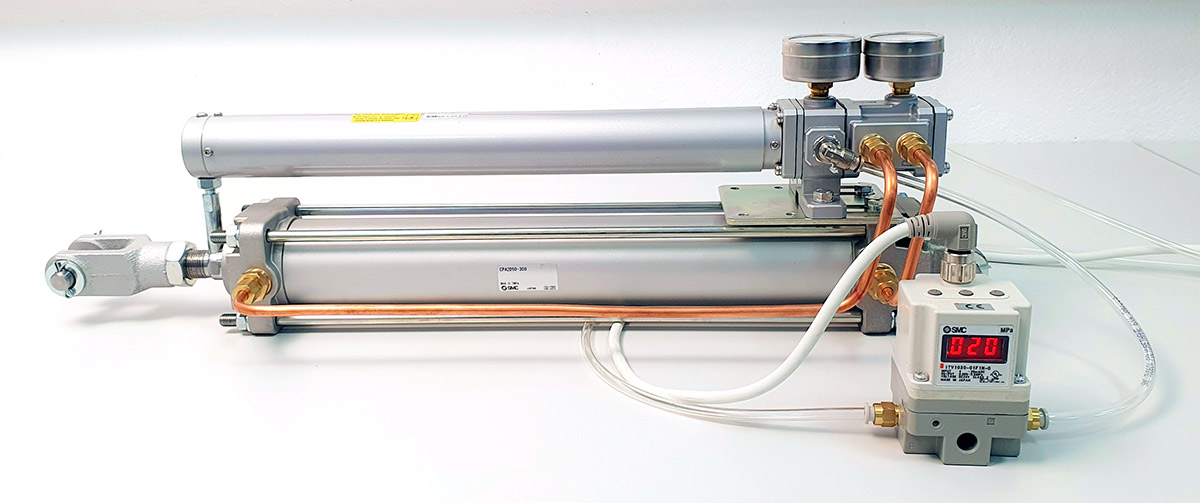

All SMC positioners can be used for double-acting actuators and, by closing one signal output, also for single-acting actuators. Double-acting actuators are equipped with two compressed air connections (one for each direction), single-acting only with one (a return spring always moves the actuator to the initial position without compressed air).

For linear or rotary actuators

The mounting of positioners on rotary actuators (ball valves, butterfly valves) differs from that on linear actuators (control valves, cylinder positioners), so that different mounting bridges and connecting parts are always required.

For some SMC series, such as the IP8*, you will find dedicated positioners for linear drives (IP800*) and for rotary drives (IP810*). For the ND9000 and ND7000 series, you can select the required accessories as an option.

Pneumatic, electric or smart

Pneumatic positioners use a signal pressure of 0.02-0.1 MPa to adjust the position of the actuator, making them suitable even for extreme environmental conditions such as temperatures of 100°C.

We also supply you with external electro-pneumatic pressure regulators e.g. the series ITV. Those can be used to convert an electrical signal into signal pressure.

lectric positioners are adjusted with an electrical signal – usually a DC signal with 4-20 mA.

Smart Positioners also have a built-in microcontroller (usually with a display). This automates calibration and allows you to set alarm limits and use digital transmission protocols (such as HART).

Everything from a single source at SMC

At SMC you will find all the necessary components for the automation of your valves: positioners, special valves up to the complete compressed air supply as well as corresponding accessories such as one-touch fittings made of stainless steel.

We also have many special versions in our product range, e.g. positioner with external position sensor without mechanical connection to the actuator, with flameproof enclosure, suitable for low temperatures down to -40°C – please contact us if you are interested.

Mounting bridges and mounting kits are also available on request and will be developed and produced by us according to your requirements.

Contact us for more information – we are happy to develop individual solutions for you, precisely tailored to your applications, wishes and requirements!

DE

DE CZ

CZ HU

HU PL

PL SI

SI