Chemical valves and needle valves are used in various industries that work with chemicals. These are, for example, large printing companies, electroplating or commercial disinfection.

The most important characteristic of the valves is that they are resistant even to aggressive chemicals such as acids, bases, or solvents. Only then the necessary security can be guaranteed.

Needle valves for adjusting the flow rate

A needle valve has a small opening and a needle-shaped, threaded valve piston. They can be used to precisely adjust the flow rate, which must be larger or smaller depending on the process and can be regulated between 0 and 12 liters per minute. Needle valves are designed to prevent bubbles from forming when slightly viscous liquids are used.

LVN – needle valves from SMC are made of a PFA material that is compatible with acids, alkalis and ultra-pure water and suitable for temperatures from 5 to 90° Celsius.

Chemical valves with LOTO function

Chemical valves are used to turn the flow mentioned above on and off.

The special LOTO function (lockout tagout) enables maintenance work to be carried out safely. With this safety feature, a valve is closed manually and fixed in this position. Accidental opening during maintenance work can thereby be avoided.

Areas of application in the chemical industry

Chemical valves and needle valves from SMC withstand aggressive chemicals such as acids and alkalis, as well as solvents used for industrial disinfection or dissolving printing ink, which can attack seals.

SMC valves for the chemical industry are especially suitable for use in the following industries:

- Fertilizer

- Plant protection

- Varnishes, paints and printing inks

- Professional cleaning and hygiene

- Textile, leather and paper auxiliaries (special chemicals as auxiliaries or finishing materials enable the manufacture, processing, finishing or care of textiles, leather products or paper)

- Adhesives

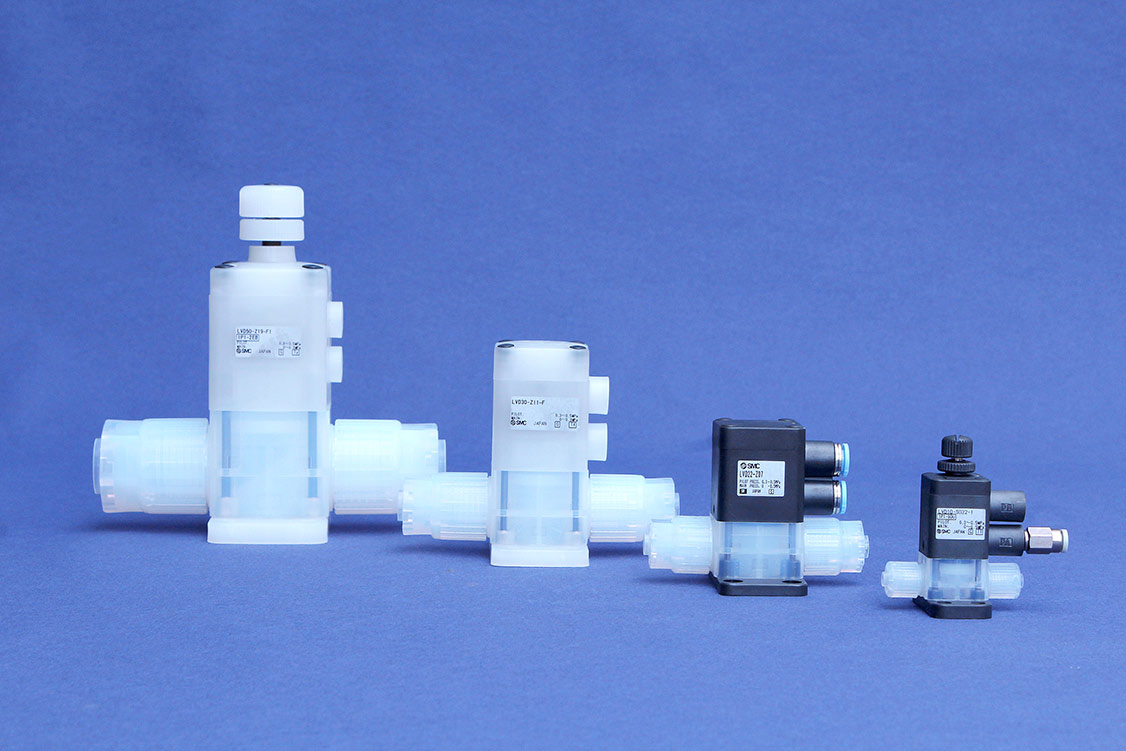

Versions

Depending on the area of application, different valves make sense. For example, if organic solvents are used, it is advised to use valves made of stainless steel. We offer a wide variety of variants and our chemists will be happy to help you make the right choice – just contact us.

We carry the following series of chemical valves:

- LVD chemical valves are pneumatically operated, with integrated screw connections, and are suitable for media temperatures of up to 100° Celsius

- LVA chemical valves also work pneumatically, with a threaded connection

- LVH chemical valves are manually operated valves with integrated screw connections or with thread and available as latching or non-latching valves

- LVQ chemical valves with integrated screw connections of various designs; both pneumatically and manually operated. There is also an option for media temperatures of up to 170° Celsius.

Features of SMC chemical valves

A new type of guide ring on the piston rod ensures a stable sealing surface by preventing lateral play of the valve seat. This extends the service life of the seals and reduces particle formation thanks to a stable working surface.

The special membrane design guarantees soft opening and closing, which prevents the formation of microbubbles.

The housing is designed for evenly flow with minimal internal dead spaces. Integrated fittings prevent residual liquid from accumulating in the pipe threads.

The body material (PFA) is suitable for ultra-pure DI water as well as for acids and bases, as it has an extremely high chemical resistance.

A damping disk absorbs the force of the piston and thus minimizes the formation of particles due to friction.

The membrane is supported by a shock absorber so that it deforms as little as possible, which ensures high back pressure resistance and durability.

You can also choose from a variety of tubing sizes.

Do you want to find out which of our needle valves and chemical valves are best suited for your application?

Contact us – our team will be happy to answer your questions.

DE

DE CZ

CZ HU

HU PL

PL SI

SI