Many industries that are already confronted with high energy costs are hit particularly hard by the current situation with escalating energy prices. Our JSXF series impulse valves offer a lot of savings potential and can thus help to reduce costs.

In our short video you will find a summary of the main advantages of our JSXF valves compared to conventional pulse valves.

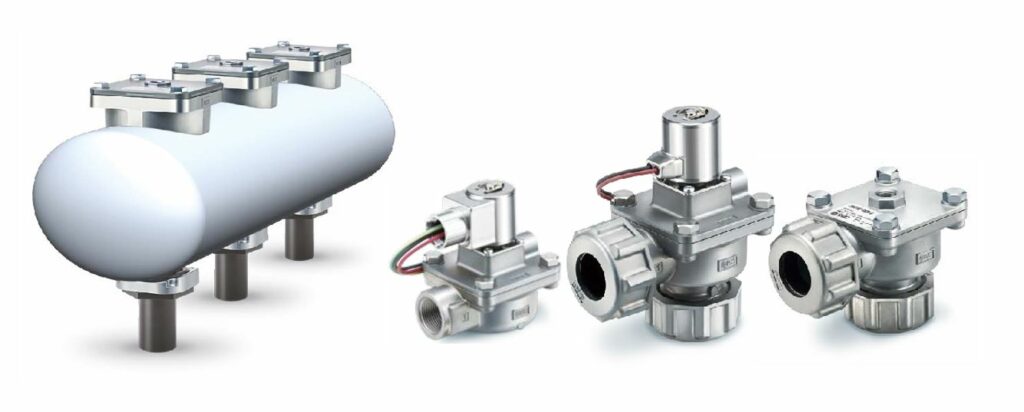

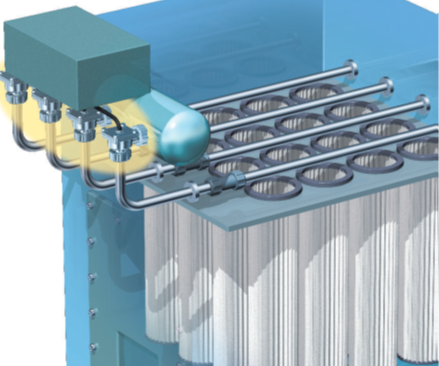

Pulse air for cleaning of pulse-jet filters in various industrial applications

Pulse valves are used wherever the filters of dust collectors are to be cleaned with the help of a pulsed air blow. This cleaning of filter bags is also called reverse pulse jet cleaning.

In this article you will find a detailed description of how impulse valves work and how they are used.

Pulsed air blow can be used in a variety of industrial applications:

- general production facilities

- steel and cement industry

- Mining

- pharmaceutical industry

- agriculture and animal farming

- food industry

- wood processing industry

- textile processing

- and many more

Lots of potential for energy savings

JSXF impulse valves are available with electric or pneumatic control, in connection sizes from 3/4 inch to 2 inch, with compression fitting, for direct mounting or with pipe thread connection and can be used for temperatures from -40 to +60°C.

If you use our optimized models of the pulse valve series JSXF, you will have numerous advantages and associated savings:

- Long service life: The JSXF valve is capable of 10 million cycles or more – based on one pulse per minute and non-stop operation, this would be a service life of more than 19 years. Many times the cleaning intervals are even longer.

- This results in very long maintenance intervals.

- Which in turn has the positive effect that the system has less downtime.

- In addition, maintenance is very easy to carry out because there are fewer parts (high-strength elastomer diaphragm instead of spring).

- Thanks to the optimized geometry, the flow rate has been increased by around 40 percent.

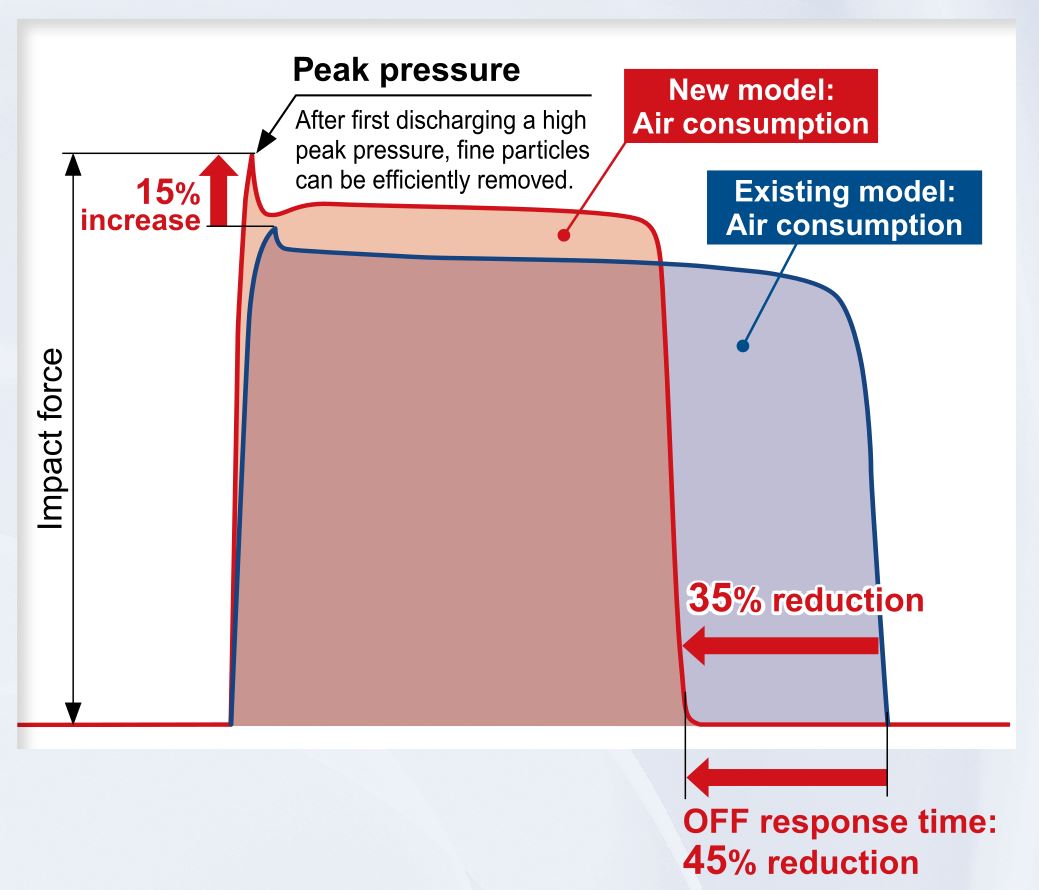

- The 15 percent higher peak blow-out pressure means that the filter can be cleaned with less pressure.

- This reduces the compressed air requirement by around 35 percent and you save valuable electrical energy, since the compressed air has to be generated by a compressor.

- The approximately 45 percent reduction in response time when switching off saves energy too.

- By saving valuable and expensive energy, you not only reduce your expenses, but also contribute to protecting our environment.

How we can support you

If you are currently using conventional valves but want to use the savings potential of our JSXF pulse valves, we will be happy to provide you with advice and assistance:

- when testing the valves

- when calculating possible savings and ROI (return on investment)

- by providing you with samples to test

Simply contact us – our team will be happy to answer your questions.

DE

DE CZ

CZ HU

HU PL

PL SI

SI