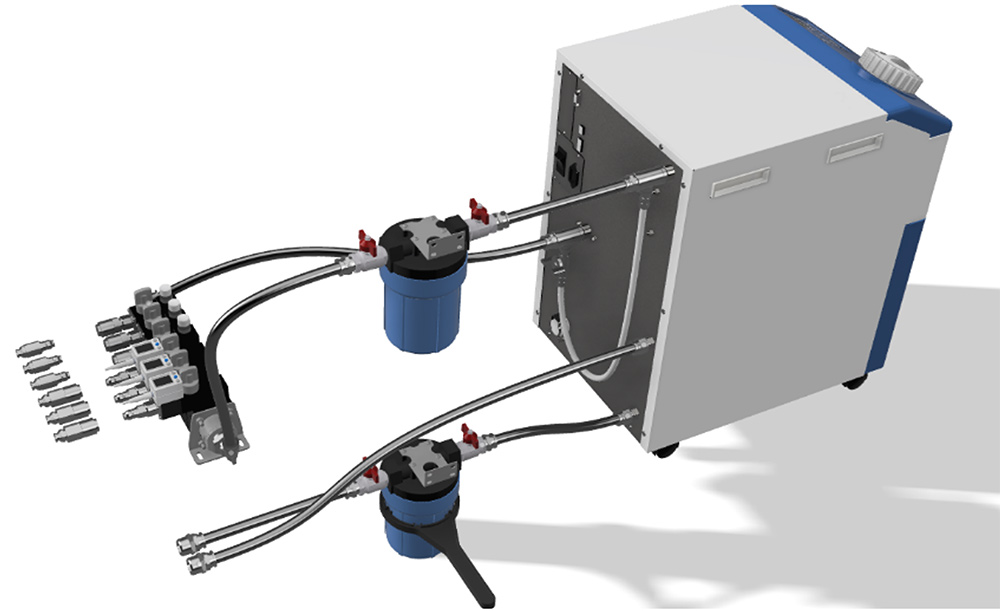

Temperature control units are used in many processes in the industrial sector where heat is generated. With us, however, you not only get the chillers, but all the products you need for your entire cooling line.

A cooling line not only consists of the connecting hoses, but also includes all components that are installed between the temperature control unit and the customer’s application.

The bypass

If the minimum flow rate cannot be guaranteed via the temperature control unit, a bypass is required. Too low flow rate can occur due to small cross-sections of the lines or applications and also if solenoid- or manualshut-off valves are installed. In this case, bypasses prevent damage to the chiller due to defective solenoid valves or accidentally closed manual shut-off valves.

Filters and pressure sensors

While filters protect the entire cooling system from contamination, pressure sensors can take over the monitoring of the filter elements.

One of the many possible applications is, for example, an automatic switching between two or more filters. As a result, your temperature control devices can run through during filter replacement.

Our FQ1 Series Filters allow filter elements to be replaced in less than two minutes, including draining the medium. In addition, no tools are required for the filter replacement.

The pressure sensor (ZSE20/ISE20 series digital pressure switch) allows the measured value to be checked during the setting process. The response time is a maximum of 1.5 ms.

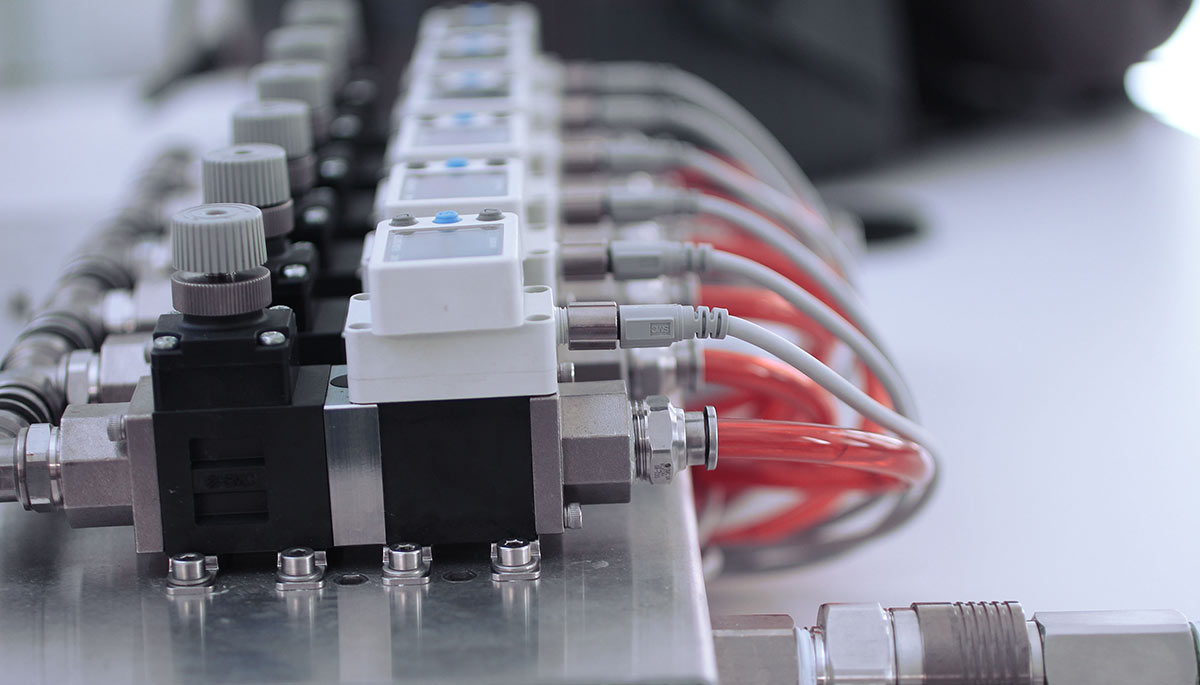

Manifolds and flow meters

With our PF3W manifolds, your tempered water can be distributed exactly. Our manifolds are configurable: with needle and shut-off valves, flow sensors, temperature meters and a variety of digital- and analog outputs.

The digital flow sensor for water (PF3W series) detects problems before they even occur, improves machine availability (integrated temperature sensor for measuring media temperature, flow control valve and IO-Link compatible) and lets you keep track of all process data (simultaneous display of the current flow rate and definable parameters like temperature).

- Usable media: water, aqueous ethylene glycol solution, deionized water

- Integrated display: 3-color / 2-piece display

- Integrated temperature sensor

- Mounting for multi-connection plate available

- Nominal flow ranges: from 0.5 to 250 l/min

Drip-free couplers

If you unplug water-carrying hoses – for maintenance purposes or if you want to change the application – drip-free couplers are recommended. These couplers allow you to lock hoses without water leaking, and you don’t have to refill or drain the pipes.

Features of our drip-free couplers of the KKA series:

- Housing material completely made of stainless steel

- Sealing material made of special FKM

- can be used for water and air

- Operating temperature range: -5 to +150°C

- Pressure: up to 10bar

- Low pressure drop via coupler

- Flow optimized

Would you like to learn more about our cooling line components and their specific properties?

Contact us – our team will be happy to answer your questions.

DE

DE CZ

CZ HU

HU PL

PL SI

SI